| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

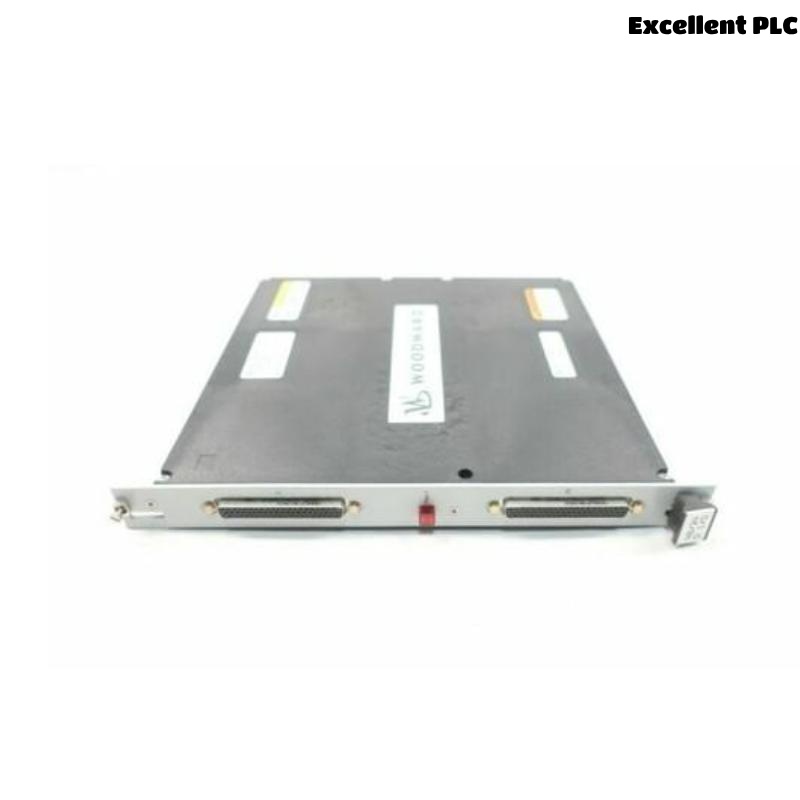

The Woodward 5466-1047 is a high-performance digital control module designed specifically for industrial gas and steam turbine applications. This unit is part of the Woodward MicroNet™ series, known for its powerful computational capability, modular architecture, and robust reliability in demanding environments. The 5466-1047 offers advanced process control functions, seamless integration into distributed control systems (DCS), and is engineered to handle real-time critical tasks with utmost precision.

Built for long-term industrial use, it is typically found in turbine generator systems, process automation, and plant safety systems where dependable control and data handling are crucial. Its architecture supports scalable I/O, redundancy options, and easy firmware upgrades, making it a future-proof choice for energy and process industries.

Product Advantages

-

High Reliability: Designed to withstand harsh industrial conditions, including high temperature, vibration, and electromagnetic interference.

-

Modular Design: Easily expandable with plug-and-play I/O modules, enabling tailored configurations for different control applications.

-

Real-Time Processing: Equipped with a fast processor and real-time operating system to ensure deterministic execution of critical functions.

-

Industry Compliance: Meets international standards for safety, performance, and emissions control, including CE and CSA certifications.

-

Redundancy Capable: Supports hot backup configurations for fault tolerance and uninterrupted operation.

-

Remote Monitoring & Diagnostics: Built-in features for remote diagnostics, event logging, and system health monitoring reduce downtime and maintenance efforts.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | Woodward 5466-1047 |

| Product Series | MicroNet™ Control Series |

| Function | Digital Turbine Control Module |

| Processor Type | High-speed Microprocessor |

| Memory | Flash-based, firmware-upgradable |

| Power Supply | 18 to 32 VDC |

| Input/Output Channels | Configurable I/O via separate modules |

| Communication Ports | Ethernet, RS-232, RS-485, ARCNET |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Shock Resistance | 20g, 11ms per MIL-STD-810F |

| Vibration Tolerance | 1.0 g from 10 to 500 Hz |

| Dimensions | 150 x 90 x 40 mm |

| Weight | 0.45 kg |

| Certifications | CE, CSA, UL, ATEX (depending on enclosure) |

Product Applications

-

Industrial Gas Turbine Control

-

Steam Turbine Regulation

-

Combined Cycle Power Plant Automation

-

Compressor and Generator Set Control

-

Emergency Shutdown Systems (ESD)

-

Remote SCADA/PLC Integration

-

Renewable Energy Systems Synchronization

-

Oil & Gas Plant Turbomachinery Control

Installation Guidelines

-

Mounting: Install the 5466-1047 module in a grounded 19-inch rack or approved enclosure designed for industrial controls.

-

Wiring: Ensure proper voltage supply (18–32 VDC) and securely connect communication cables.

-

Environment: Maintain ambient conditions within the recommended temperature and humidity range.

-

Firmware Setup: Load application-specific firmware using the Woodward software toolkit before operation.

-

Grounding: Ensure effective chassis grounding to avoid electrical interference.

-

Diagnostics: Use built-in diagnostic tools to verify hardware integrity and communication readiness.

10 De-AI-Style FAQs

Q1: What is the primary use of the Woodward 5466-1047 module?

A1: It is mainly used for the control of industrial turbines, ensuring precise regulation and safe operation.

Q2: Can the 5466-1047 be used in hazardous environments?

A2: Yes, when housed in an ATEX or explosion-proof certified enclosure, it is suitable for hazardous locations.

Q3: How do I upgrade the firmware?

A3: Firmware can be upgraded via Ethernet using Woodward’s control software while the system is in maintenance mode.

Q4: Does this model support redundant control?

A4: Yes, it can be configured in redundant mode to enable fault tolerance and continuous operation.

Q5: Is this product suitable for offshore oil platforms?

A5: Yes, with appropriate environmental protection, it’s well-suited for marine and offshore applications.

Q6: What kind of maintenance does it require?

A6: It requires minimal maintenance. Periodic inspection and cleaning of connections and firmware updates are sufficient.

Q7: How many I/O modules can be added?

A7: It supports multiple I/O expansion modules depending on the rack and power supply capacity.

Q8: What communication protocols are supported?

A8: It supports Ethernet/IP, Modbus TCP, RS-232, RS-485, and ARCNET, allowing wide integration options.

Q9: Can it be integrated with legacy systems?

A9: Yes, it is backward-compatible and can be adapted through interface modules.

Q10: What diagnostic features does it offer?

A10: The unit features onboard LEDs, software diagnostics, event logs, and watchdog timers.

6 Related or Same-Series Models

-

Woodward 5466-1000

-

Woodward 5466-1120

-

Woodward 5466-1035

-

Woodward 5466-1045

-

Woodward 5466-1050

-

Woodward 5466-1063

6 Popular Models from the Same Brand

| Model | Function | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|

| 5501-380 | Remote I/O Module | 24 VDC | 220 x 150 x 80 | 2.1 kg |

| 5464-544 | Analog Input Module | 24 VDC | 180 x 160 x 60 | 1.8 kg |

| 8237-124 | Digital Governor Control | 24 VDC | 250 x 200 x 100 | 3.2 kg |

| 9905-463 | Generator Load Sharing Controller | 24 VDC | 240 x 160 x 90 | 2.9 kg |

| 505E | Steam Turbine Controller | 18–32 VDC | 290 x 280 x 110 | 4.5 kg |

| 2301E-DC | Load Sharing and Speed Control | 18–40 VDC | 215 x 125 x 65 | 1.6 kg |

Excellent PLC

Excellent PLC