| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

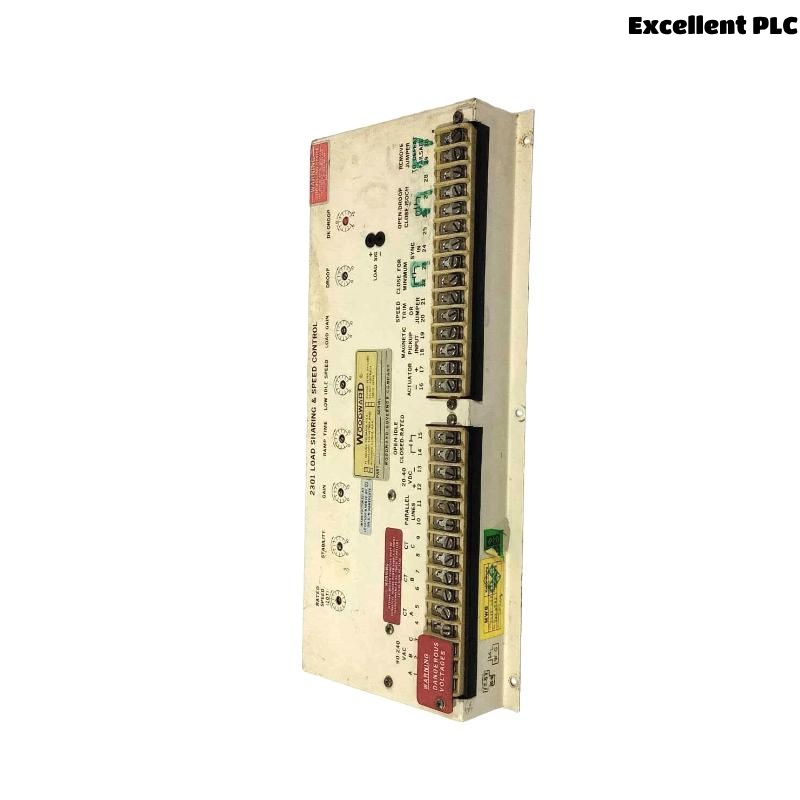

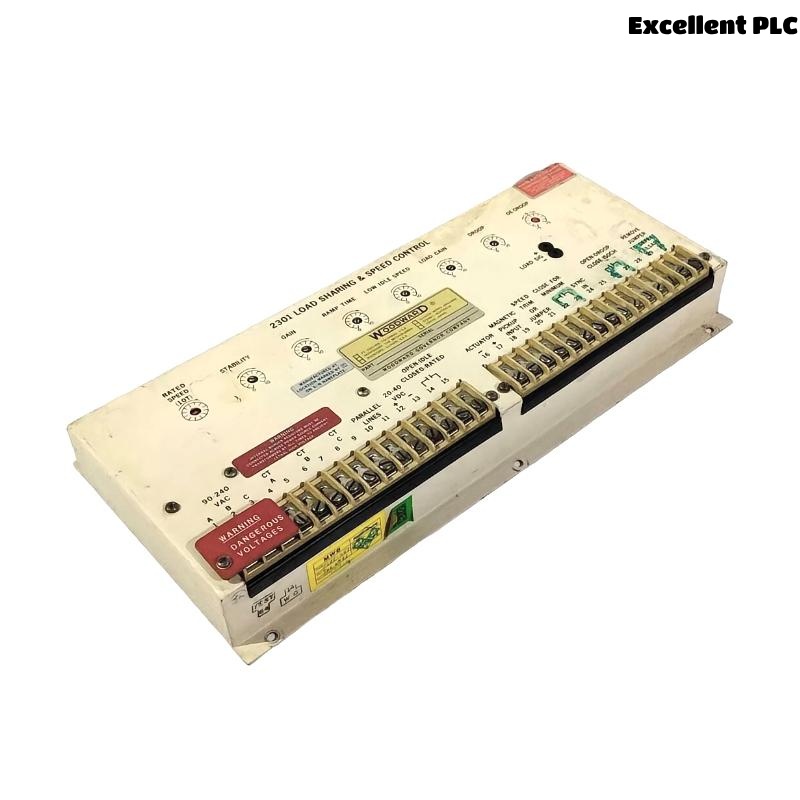

The Woodward 8271-467 Load Sharing and Speed Control Module is a robust and intelligent controller designed to govern engine speed and manage load sharing across multiple generator sets operating in parallel. Purpose-built for applications where precise control, synchronization, and stable power distribution are essential, this module is part of Woodward’s acclaimed 2301D/LS and legacy series.

Equipped with analog and digital interfacing capabilities, the 8271-467 supports real-time communication between generators, allowing for uniform power contribution while maintaining rated frequency and stability. It enables both droop and isochronous load sharing modes, making it suitable for utility-grade applications and isolated power systems.

With proven dependability in power generation, marine propulsion, and oil & gas sectors, this controller is a cornerstone of distributed energy resource (DER) systems and backup power infrastructures requiring unmatched control precision.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 8271-467 |

| Product Type | Load Sharing and Speed Control Module |

| Control Mode | Isochronous / Droop / Base Load / Process Control |

| Input Voltage | 18–32 VDC (Nominal: 24 VDC) |

| Power Consumption | ≤ 15 W |

| Speed Sensor Input | Magnetic Pickup (MPU), 1–30 Vrms, 2–10 kHz |

| Speed Range | 500–15,000 Hz (engine-dependent) |

| Actuator Output | 0–200 mA current output or PWM |

| Load Sharing Line | ±3 VDC |

| Analog Inputs | 2 Configurable (0–5 VDC / 4–20 mA) |

| Digital Inputs | 6 (configurable for start/stop, mode select, raise/lower) |

| Digital Outputs | 4 (alarms, trip, relay control) |

| Communication Interfaces | RS-232 for configuration and monitoring |

| Control Interface Software | Woodward ToolKit |

| Mounting | Panel/DIN rail mount |

| Protection Class | IP65 (when enclosed) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -55°C to +85°C |

| Dimensions (W × H × D) | 150 x 90 x 40 mm |

| Weight | 1.87 kg |

| Certifications | CE, UL, CSA, RoHS Compliant |

Product Applications

The Woodward 8271-467 controller serves as a central element in multi-unit generator and engine systems, where it ensures reliable synchronization and proportional power delivery. Key application areas include:

-

Power Plants (Prime and Standby)

Controls engine-driven generators in isolated or utility-parallel operation for stable frequency and voltage. -

Marine Vessel Propulsion Systems

Maintains steady engine speed and load balancing in propulsion and auxiliary generators aboard ships. -

Oil & Gas Processing Facilities

Manages power generation units operating in load sharing across oil fields, refineries, and gas processing stations. -

CHP (Combined Heat and Power) Systems

Balances energy output between electrical and thermal demands in cogeneration facilities. -

Mobile Power Units and Rental Gensets

Enables rapid deployment and synchronization of multiple gensets for temporary power installations. -

Industrial Plants with Distributed Loads

Ensures equitable load management among several generators operating within large industrial facilities.

Product Advantages

The Woodward 8271-467 Load Sharing and Speed Control Module offers multiple operational benefits, enhancing both efficiency and safety:

-

Precision Load Sharing

Supports accurate and proportional load division across parallel units to prevent overloading and underutilization. -

Versatile Control Modes

Functions in isochronous, droop, base load, and process control modes for flexible power management. -

Fast Synchronization

Reduces synchronization time and transient instability during generator on/offline switching. -

Field Configurable

Easily programmable using Woodward ToolKit software to fit custom application logic and input/output preferences. -

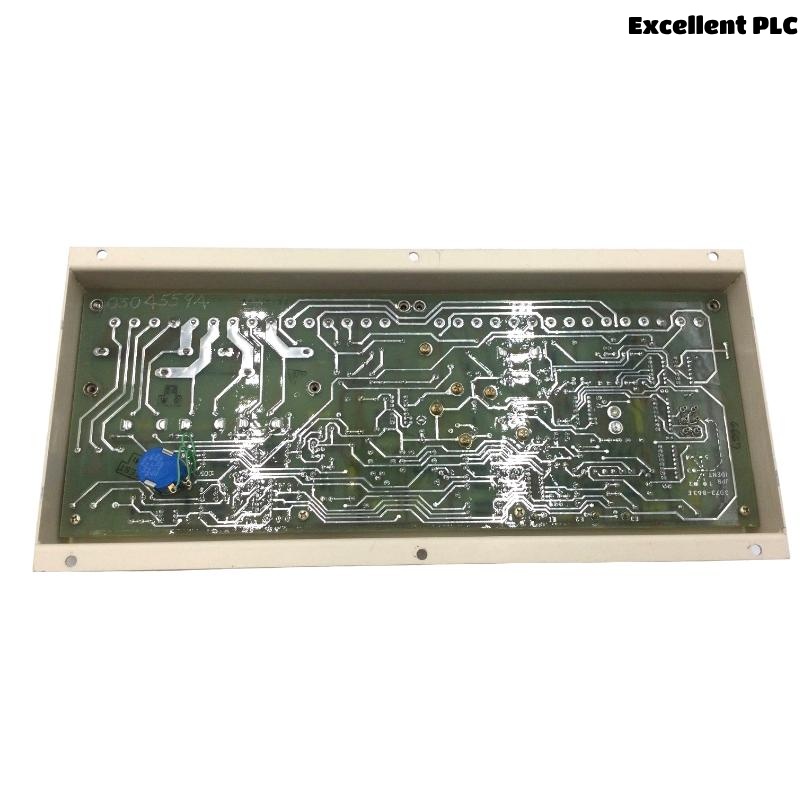

High Environmental Resilience

Designed to function reliably in extreme temperatures, vibrations, and industrial contaminants. -

Low System Integration Cost

Eliminates the need for additional synchronization hardware or logic controllers in many systems. -

Seamless Integration with Woodward Ecosystem

Works natively with other Woodward components such as actuators, governors, and power management solutions.

FAQ (Frequently Asked Questions)

-

What is the main function of the Woodward 8271-467?

-

It controls engine speed and enables load sharing among multiple generators operating in parallel.

-

-

Is this controller suitable for utility grid-tied applications?

-

Yes, it can operate in both isolated and utility-parallel configurations.

-

-

Can the module support process control?

-

Yes, it includes a process control mode for maintaining set process values (e.g., pressure, temperature).

-

-

What kind of actuators does it control?

-

It supports current-driven actuators and can be configured for PWM or voltage output in certain setups.

-

-

Is remote monitoring supported?

-

While it has RS-232 for local communication, remote support is possible with optional gateways or HMI integration.

-

-

Does it require software to configure?

-

Yes, configuration is done through Woodward ToolKit software on a PC.

-

-

What kind of input sensors does it accept?

-

It accepts MPU (magnetic pickup) signals from engine flywheels for speed measurement.

-

-

What happens if one generator fails?

-

The controller can detect faults and initiate safe load redistribution or trip procedures.

-

-

How many digital I/O ports does it support?

-

It includes 6 digital inputs and 4 digital outputs, all programmable.

-

-

Can it be used with Woodward actuators and governors?

-

Absolutely. It is optimized for integration with Woodward actuators and governor systems.

Related Models (Same Series or Functionally Equivalent)

| Model | Type | Control Mode | Features | Typical Use Case |

|---|---|---|---|---|

| 8271-467 | Load Sharing & Speed Control | Isochronous / Droop | RS-232, 0–200 mA, process control support | Multi-genset power plants |

| 8271-467A | Load Sharing & Speed Control | Isochronous / Droop | Enhanced diagnostics, extended temperature range | Offshore platforms, military vessels |

| 2301D-EC | Digital Speed Controller | Isochronous / Droop | Ethernet config, CANbus, integrated LCD | Industrial engines, advanced automation |

| 9905-940 | Generator Controller | Load Sharing + Protection | Genset control with protection relays | Emergency backup systems |

| 723PLUS | Engine Management System | Full Logic + Load Control | Multi-unit logic and I/O expansion capabilities | Oil & gas fields, refineries |

| LS-5 | Load Sharing Controller | Isochronous + Sync | Load transfer and synchronizing relay logic | Utility switching and genset management |

Popular Models from the Same Brand (Woodward)

| Model | Type | Primary Function | Application Area |

|---|---|---|---|

| 2301D | Digital Speed Control | Speed control and load sharing | Industrial generators |

| 505XT | Steam Turbine Control | Speed, extraction, and load management | Medium-to-large steam turbines |

| SPM-D2 | Synchronizer Module | Auto-synchronization of voltage and phase | Backup genset operation |

| ProAct IV | Integrated Actuator Controller | Throttle + actuator in one device | Retrofit engine control |

| EasYgen-3500XT | Genset Controller | Full genset automation and monitoring | Industrial/commercial power systems |

| 723PLUS | Engine Management System | Load sharing, speed, and full logic control | Oilfield engines, power generation |

Excellent PLC

Excellent PLC