| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

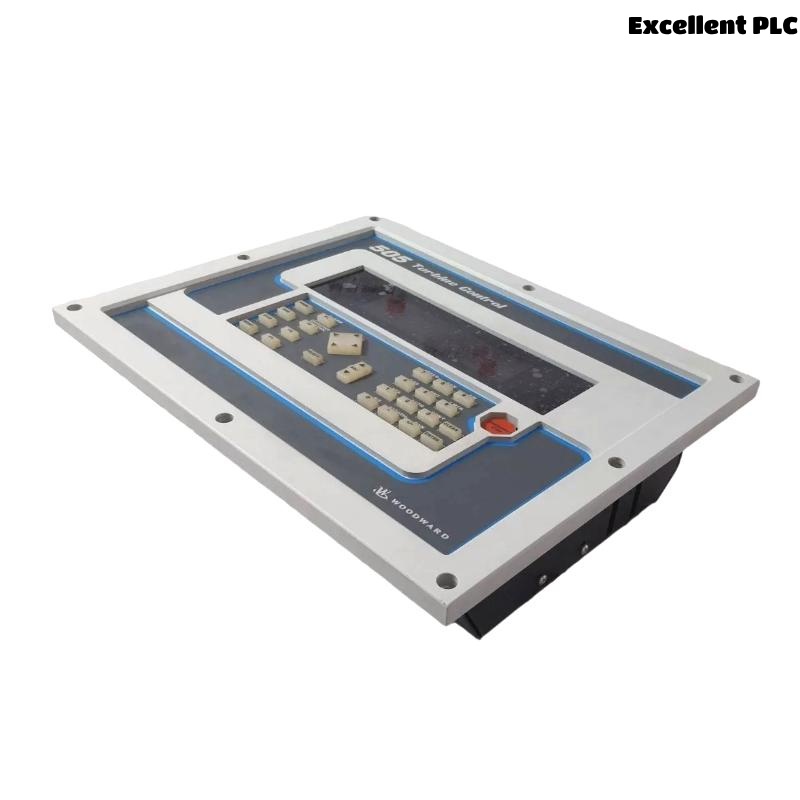

The Woodward 9907-167 (505E) is a high-performance digital governor specifically designed for controlling single-valve steam turbines used in industrial, marine, and power generation applications. This model belongs to the Woodward 505E series, which is known for providing precise turbine speed and load control, rapid response, and robust system integration.

Equipped with a powerful microprocessor and built-in touchscreen HMI, the 505E simplifies system monitoring, parameter adjustment, and diagnostics. The 9907-167 is designed for ease of retrofit, supporting a wide range of input signals and control outputs, and is suitable for both mechanical and electrical trip systems. This model can operate in multiple control modes such as speed control, load control, and process control, depending on the user’s configuration.

The 505E is widely respected for its high reliability, field-proven software platform, and compliance with international safety standards. It is ideal for industrial users seeking a flexible and efficient steam turbine control system that enhances operational performance and minimizes downtime.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Woodward 505E Digital Governor |

| Model Number | 9907-167 |

| Control Type | Microprocessor-based digital steam turbine governor |

| Supported Turbines | Single-valve steam turbines |

| Display Interface | Built-in color touchscreen HMI |

| Power Supply | 18–32 V DC |

| Speed Input Range | 0.5 – 25,000 Hz (magnetic pickup or active speed sensor) |

| Control Modes | Speed, Load, Isochronous, Droop, Process Control |

| Analog Inputs | 4–20 mA, 0–5 V, configurable analog inputs |

| Relay Outputs | Up to 10 relays (configurable) |

| Digital I/O | Discrete digital inputs and outputs |

| Communication Ports | RS-232, RS-485, Modbus RTU, TCP/IP (optional) |

| Trip System Support | Mechanical and electrical trip interfaces |

| Ambient Operating Temp. | -20°C to +70°C |

| Humidity Range | 5% to 95% RH, non-condensing |

| Mounting Type | Panel or rack mounted |

| Enclosure Protection | IP20 |

| Certifications | CE, UL, CSA |

| Dimensions (W × H × D) | 355.6 x 279.4 x 101.6 mm |

| Weight | 3.6 kg |

Product Applications

The Woodward 9907-167 505E Digital Governor is engineered to meet the demanding control needs of single-valve steam turbines across various industries:

-

Industrial Power Generation

Provides stable steam turbine operation in small and medium-sized power plants. -

Cogeneration (CHP) Systems

Maintains accurate turbine speed and load for combined heat and power applications. -

Petrochemical Facilities

Controls steam turbines driving process compressors or pumps. -

Pulp and Paper Industry

Used in process steam turbines to maintain load balance and process synchronization. -

Food & Beverage Plants

Enables safe and efficient operation of process steam systems. -

Turbine Retrofits

Ideal for replacing analog or relay-based control systems with a digital, more flexible platform.

Product Advantages

-

Integrated Touchscreen Interface

The built-in HMI allows intuitive configuration, monitoring, and fault diagnosis without external tools. -

Versatile Communication Options

Easily integrates with DCS, PLC, or SCADA via Modbus or TCP/IP. -

Flexible Control Modes

Supports multiple operational modes including speed, load, and process control. -

Rapid Response Time

Fast control response ensures protection and efficiency during transients. -

Enhanced Diagnostics and Logging

Built-in system health checks and event logs simplify troubleshooting and preventive maintenance. -

Wide Sensor Compatibility

Works with magnetic pickups and active speed sensors across a wide frequency range. -

Robust Industrial Build

Designed for harsh industrial environments with high vibration and temperature resistance.

Frequently Asked Questions (FAQ)

-

What type of turbine is the 9907-167 designed to control?

It is specifically designed for single-valve steam turbines. -

Does this governor include a touchscreen interface?

Yes, it includes an integrated color touchscreen HMI for control and configuration. -

What communication protocols are supported?

RS-232, RS-485, Modbus RTU, and optional Modbus TCP/IP are supported. -

Is the unit suitable for retrofitting older control systems?

Yes, it’s commonly used to replace analog governors in turbine retrofit projects. -

Can it perform in process control mode?

Yes, it can operate in process control, isochronous, and load control modes. -

Does it support electrical and mechanical trip systems?

Yes, the 9907-167 supports both electrical and mechanical trip mechanisms. -

What types of speed inputs are accepted?

It supports magnetic pickups and active sensors from 0.5 to 25,000 Hz. -

Is this governor compliant with international certifications?

Yes, it is CE, UL, and CSA certified. -

What is the operating temperature range?

It functions effectively in environments ranging from -20°C to +70°C. -

How many configurable relays are included?

The unit offers up to 10 user-configurable relay outputs.

Recommended Related Models (Same Series or Similar Function)

| Model | Model Number | Description |

|---|---|---|

| Woodward 505E | 9907-164 | Similar model with alternative I/O configuration |

| Woodward 505E | 9907-165 | 505E variant with extended Modbus communication |

| Woodward 505E | 9907-166 | High-performance 505E with process control tuning |

| Woodward 505XT | 9907-202 | Steam turbine controller with enhanced touchscreen HMI |

| Woodward 505D | 9905-950 | Digital steam turbine control for mechanical drive systems |

| Woodward 9907-1183 | 9907-1183 | Digital governor for engine and turbine applications |

Recommended Popular Woodward Models

| Model | Model Number | Application |

|---|---|---|

| Woodward EasyGen 3500 | 8440-2085 | Generator control with load sharing and paralleling |

| Woodward CPC-II | 9907-1200 | Current-to-pressure converter for valve actuation |

| Woodward UG-25+ | 8273-124 | Mechanical-hydraulic governor with electronic assist |

| Woodward ProTech 203 | 9907-147 | Triple modular overspeed protection system |

| Woodward 723 Plus | 8440-2080 | Advanced engine/turbine controller with networking |

| Woodward 2301D Digital | 8200-1304 | Digital controller for speed and load sharing control |

Excellent PLC

Excellent PLC