| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

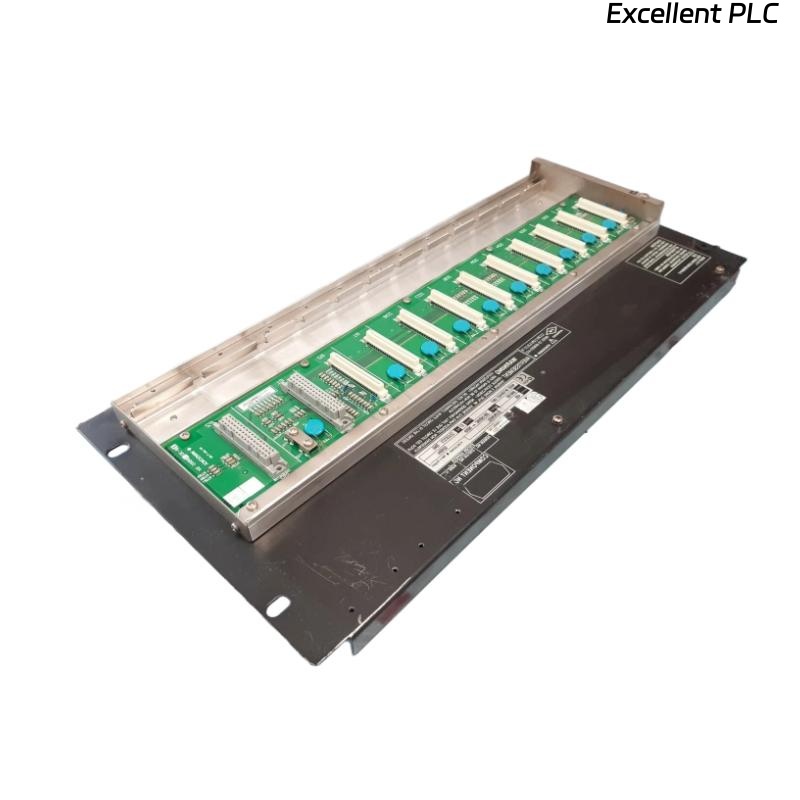

The Yokogawa AFG84D Duplexed Field Control Station Migration Toolkit is a highly specialized system toolkit designed to facilitate the migration, configuration, and maintenance of duplexed field control stations (FCS) within Yokogawa’s CENTUM distributed control system (DCS) architecture. This toolkit provides a comprehensive solution for upgrading and transitioning from legacy control stations to modern, high-performance duplexed FCS platforms without disrupting plant operations.

The AFG84D toolkit ensures seamless migration of control logic, I/O configurations, and communication parameters, reducing engineering time and minimizing operational risks during system modernization. It supports advanced redundancy features that ensure continuous process control even in the event of hardware or communication failures.

Designed for reliability and compatibility, the AFG84D integrates effortlessly with Yokogawa’s CENTUM VP and CENTUM CS 3000 systems, ensuring data integrity, synchronization, and smooth system operation. Its flexible design allows for both partial and full system migrations, enabling process industries to adopt modern control technologies while retaining existing assets.

Technical Specifications

| Parameter | Description |

|---|---|

| Manufacturer | Yokogawa Electric Corporation |

| Model | AFG84D |

| Product Type | Duplexed Field Control Station Migration Toolkit |

| System Compatibility | CENTUM VP, CENTUM CS 3000, CENTUM CS |

| Processor Configuration | Duplexed redundant CPU modules |

| Communication Interface | Vnet/IP and legacy Vnet support |

| Supported Control Functions | Continuous, batch, and sequence control |

| Control Cycle Time | 1 ms to 100 ms (configurable) |

| Memory Capacity | Up to 512 MB (depending on configuration) |

| Redundancy Features | Duplexed CPU, I/O modules, and communication paths |

| Power Supply | Dual redundant 24 V DC power inputs |

| Input/Output Compatibility | Compatible with AIO, DIO, and mixed I/O modules |

| Network Redundancy | Fully redundant communication network supported |

| Environmental Conditions | Designed for industrial-grade operation |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 10% to 90% RH (non-condensing) |

| EMC Compliance | Conforms to IEC61000-4 series |

| Diagnostics | Self-diagnosis and redundancy status monitoring |

| Dimensions (W x H x D) | 207 × 265.9 x 482.6 mm |

| Weight | 8 kg |

| Mounting Type | Panel or cabinet-mounted |

| Software Tools Included | Engineering configuration tool, migration assistant, diagnostics utility |

| Certification | CE, UL, CSA, RoHS compliant |

Applications

The Yokogawa AFG84D Duplexed Field Control Station Migration Toolkit is widely applied in process industries where high system reliability and long operational continuity are essential. Key application areas include:

-

Oil and Gas Refining: Facilitates control system migration for refinery process units, ensuring continuous operation during system upgrade.

-

Chemical and Petrochemical Plants: Enables modernization of existing control systems with minimal downtime and no data loss.

-

Power Generation: Provides reliable redundancy for turbine, boiler, and auxiliary control systems.

-

Pharmaceutical Manufacturing: Supports validated process control transitions while maintaining regulatory compliance.

-

Water and Wastewater Treatment: Ensures continuous control performance during legacy system replacement.

-

Steel and Pulp Mills: Maintains real-time process control during system expansion and digitalization efforts.

This toolkit is ideal for plants planning long-term control system upgrades, ensuring smooth integration between existing and new hardware generations.

Advantages

-

Seamless Migration: Allows safe and efficient transition from legacy control systems to modern duplexed FCS with minimal process interruption.

-

Full Redundancy: Provides dual CPU, communication, and power redundancy to eliminate single points of failure.

-

Enhanced System Reliability: Continuous control operation even during hardware switchover or fault conditions.

-

Comprehensive Diagnostic Tools: Built-in software utilities enable real-time system monitoring and fault identification.

-

Flexible Configuration: Supports both full and partial system migrations depending on plant requirements.

-

Long-Term Compatibility: Ensures integration with existing Yokogawa systems and software environments.

-

Improved Maintainability: Easy access to configuration tools and hot-swappable modules minimize maintenance downtime.

-

Future-Ready Design: Supports latest Vnet/IP communication protocols while maintaining backward compatibility with older systems.

FAQ

1. What is the primary function of the AFG84D Migration Toolkit?

It facilitates the migration of legacy Yokogawa control stations to duplexed field control station configurations while preserving existing logic, I/O, and communication parameters.

2. Can the AFG84D toolkit support online migration?

Yes, it supports online migration in duplexed environments, allowing one control path to remain active while the other undergoes upgrade or configuration.

3. What types of control applications are supported by the AFG84D?

It supports continuous, batch, and sequence control applications typical in process industries.

4. Does the AFG84D require new I/O modules for migration?

Not necessarily. It is designed to be backward compatible with existing Yokogawa AIO, DIO, and mixed I/O modules.

5. How does redundancy work in the AFG84D?

Redundancy is implemented in CPUs, communication modules, and power supplies. In case of failure, automatic switchover ensures uninterrupted process control.

6. Can the AFG84D be integrated with both Vnet and Vnet/IP networks?

Yes, it supports both legacy Vnet and modern Vnet/IP protocols, ensuring flexibility during system migration.

7. What diagnostic functions are available in the toolkit?

It includes self-diagnosis, redundancy status monitoring, event logging, and communication fault detection utilities.

8. How is system configuration managed in the AFG84D?

Configuration is handled through Yokogawa’s engineering tools, which allow parameter setting, system mapping, and verification through a graphical interface.

9. Is the AFG84D compatible with CENTUM VP systems?

Yes, it is fully compatible with CENTUM VP and CENTUM CS 3000 control systems, supporting smooth system transition and operation.

10. How does the AFG84D ensure data consistency during migration?

The toolkit synchronizes all control data between the old and new systems in real time, ensuring process continuity and data integrity throughout migration.

Recommended Related Models (Same Series)

| Model | Description |

|---|---|

| AFG84S | Single Field Control Station Migration Toolkit |

| AFS40D | Duplexed Communication Processor Module |

| AFS30S | Field Control Processor (Single) |

| AFS40C | Redundant Communication Control Module |

| AFV10D | Vnet/IP Interface Unit |

| AFA11S | Field Control Base Unit |

Popular Yokogawa Models (Same Brand)

| Model | Description |

|---|---|

| ADV151 | Digital Output Module |

| AAI141 | Analog Input Module |

| AAP135 | Analog Output Module |

| PW482 | Power Supply Module |

| CP345 | Processor Control Module |

| ALR121 | Relay Output Module |

Excellent PLC

Excellent PLC