| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

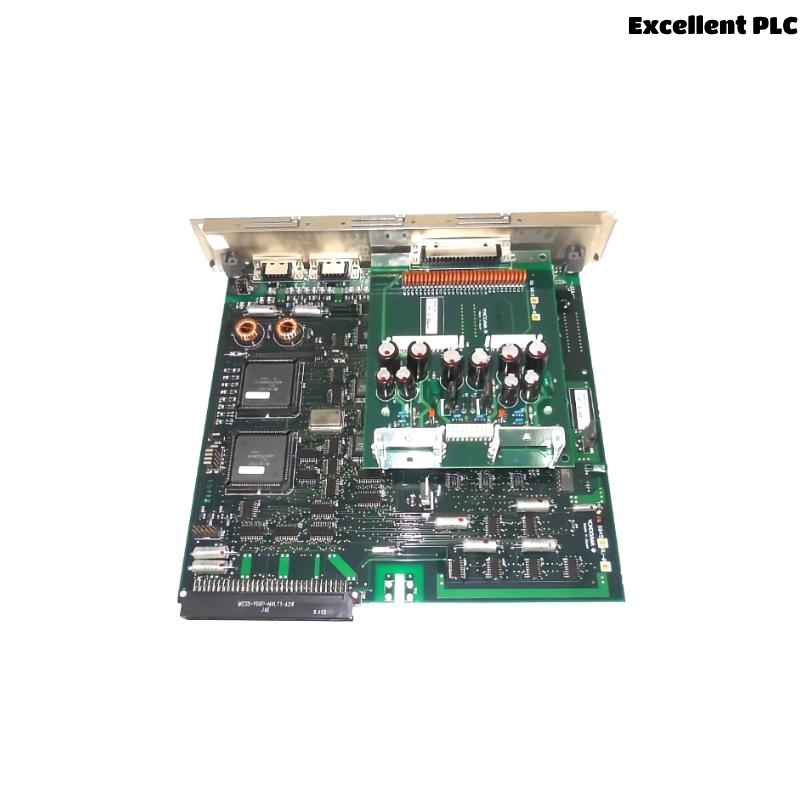

The Yokogawa AIP121-S2 Control Module is a highly reliable analog input processing unit designed specifically for integration within Yokogawa’s CENTUM VP distributed control system. This module is engineered to provide accurate and stable analog signal acquisition from field instruments, offering a vital interface between process signals and the control system.

Built with precision and ruggedness, the AIP121-S2 enables plants to maintain continuous monitoring and control of key process variables such as temperature, pressure, flow, and level. Its enhanced signal processing capabilities ensure minimal noise interference, contributing to highly reliable data acquisition even in harsh industrial environments.

The AIP121-S2 is designed with modularity in mind, facilitating easy installation, maintenance, and replacement within Yokogawa’s rack-based control systems. Its compact form factor allows for efficient use of control cabinet space without compromising performance.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | AIP121-S2 |

| Module Type | Analog Input Processing Module |

| Input Signal Type | 4-20 mA current input, Voltage input (0-10 V) |

| Number of Channels | 8 channels |

| Input Impedance | Approx. 250 Ω (for current input) |

| Accuracy | ±0.1% of span |

| Response Time | 100 ms (typical) |

| Power Supply | +5 V DC (from mainframe) |

| Operating Temperature Range | 0°C to 55°C |

| Storage Temperature Range | -20°C to 70°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Dimensions (W × H × D) | 150 x 90 x 70 mm |

| Weight | 2.5 kg |

| Mounting | Rack-mount within Yokogawa mainframe |

| Certifications | CE, UL |

Product Applications

-

Process Automation: Provides accurate analog signal acquisition for variables like temperature, pressure, flow, and level in process plants.

-

Petrochemical Industry: Ensures stable data acquisition from hazardous and complex chemical processing systems.

-

Power Plants: Supports control and monitoring of critical parameters to maintain stable and efficient plant operations.

-

Water Treatment Facilities: Enables precise monitoring of water quality parameters and treatment process variables.

-

Pharmaceutical Manufacturing: Facilitates compliance with regulatory standards by providing reliable process data acquisition.

-

Food and Beverage Processing: Maintains quality control by ensuring accurate measurement of process variables.

Product Advantages

-

High Accuracy and Stability: The module provides precise measurement with minimal drift, essential for critical process control.

-

Multi-Channel Capability: Supports 8 input channels, allowing centralized analog data acquisition.

-

Compact and Modular Design: Fits seamlessly into Yokogawa’s rack-based systems, facilitating easy installation and maintenance.

-

Wide Operating Conditions: Designed to perform reliably in industrial environments with varying temperatures and humidity.

-

Robust Signal Processing: Minimizes electrical noise and interference, ensuring stable and clean analog signals.

-

Integrated Diagnostics: Enables early detection of sensor faults and wiring issues, reducing maintenance efforts.

-

Seamless Integration: Fully compatible with CENTUM VP systems, supporting plant-wide automation architecture.

-

Certified and Compliant: Holds CE and UL certifications, ensuring safety and quality compliance.

Frequently Asked Questions (FAQ)

-

What types of analog signals does the AIP121-S2 accept?

It accepts both 4-20 mA current signals and voltage signals from 0 to 10 V. -

How many channels are available on this module?

The module supports 8 independent input channels. -

What is the typical accuracy of the AIP121-S2?

The accuracy is ±0.1% of span, suitable for precise control applications. -

Can this module operate in high humidity environments?

Yes, it is designed to operate in 5% to 95% relative humidity, non-condensing. -

What is the power supply requirement?

It is powered by +5 V DC supplied from the Yokogawa mainframe rack. -

How does this module integrate with the CENTUM VP system?

It is designed for plug-in installation within Yokogawa mainframes, communicating directly with the CENTUM VP controller. -

Is the AIP121-S2 suitable for hazardous areas?

The module itself does not have intrinsic hazardous area certification; additional protective measures are necessary. -

What are the physical dimensions of the module?

Dimensions are 150 x 90 x 70 mm. -

Does the module provide any self-diagnostic features?

Yes, it can detect sensor failures and wiring faults to alert operators. -

Which industries commonly use the AIP121-S2?

Commonly used in petrochemical, power generation, water treatment, pharmaceutical, and food & beverage industries.

Recommended Models – Same Series or Related

| Model Number | Description | Key Features |

|---|---|---|

| AIP121-S1 | Analog Input Module (single version) | 4 input channels, standard model |

| AIP122-S2 | Analog Input Module with temperature input | Supports thermocouple and RTD inputs |

| AOP121-S2 | Analog Output Module | Provides analog outputs for control valves |

| AIP123-S2 | High-Speed Analog Input Module | Faster response time for dynamic signals |

| AIP124-S2 | Multi-range Analog Input Module | Supports multiple input ranges for flexibility |

| AIP125-S2 | Isolated Analog Input Module | Enhanced noise immunity and isolation |

Recommended Popular Models – Yokogawa Brand

| Model Number | Description | Typical Application |

|---|---|---|

| CENTUM VP R6 | Distributed Control System | Large-scale plant automation |

| ProSafe-RS | Safety Instrumented System | Safety-critical processes |

| YS1700 | Compact Modular Control System | Small to medium automation |

| SMARTDAC+ GX20 | Data Acquisition and Control Unit | Process monitoring |

| Vnet/IP Gateway | Network Communication Gateway | System integration management |

| STARDOM FCN | Network-based Distributed Control System | Flexible automation solutions |

Excellent PLC

Excellent PLC