| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

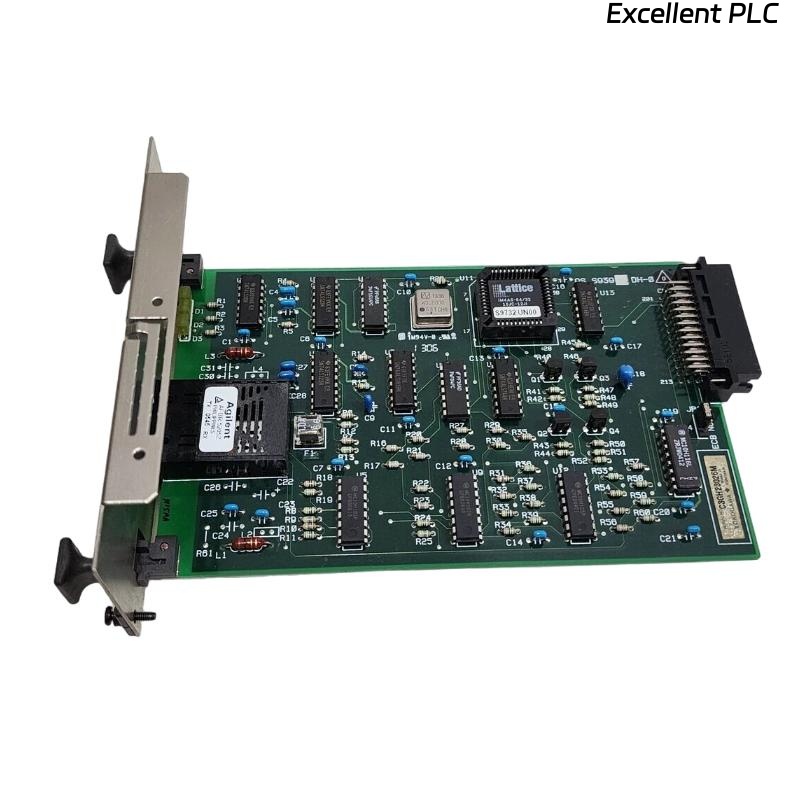

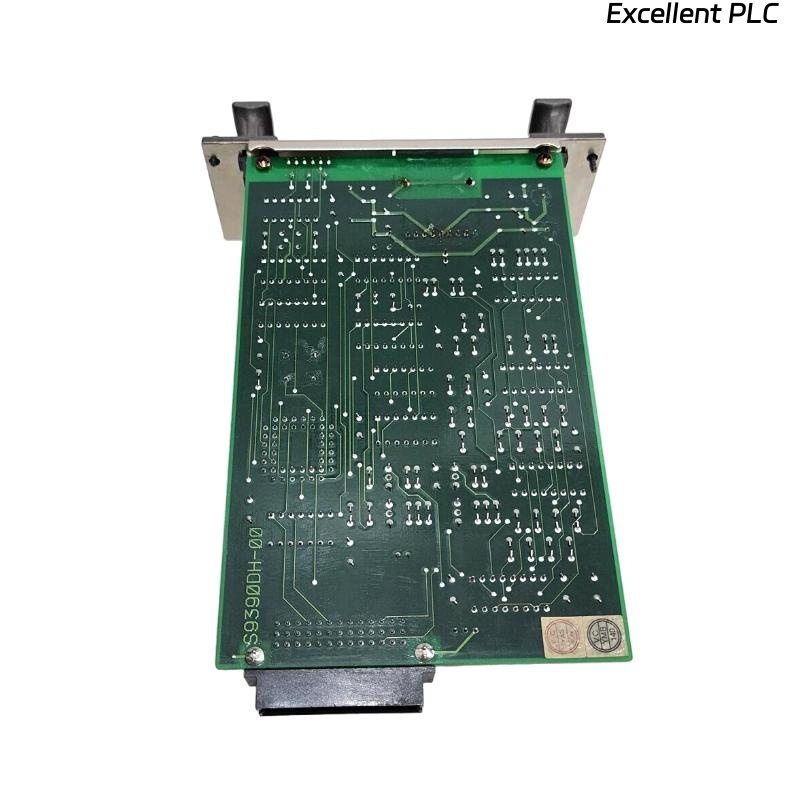

The Yokogawa AIP588 Electrical Transceiver RIO I/O Module is a high-performance interface module designed for reliable and efficient data communication within distributed control systems (DCS). It serves as an essential component in the Yokogawa CENTUM VP architecture, facilitating seamless integration of field devices and process controllers. This module ensures accurate signal transmission and reception, supports a wide range of I/O types, and provides robust electrical isolation, making it ideal for critical industrial applications such as oil & gas, chemical processing, power generation, and water treatment.

The AIP588 module is engineered to deliver exceptional reliability under harsh industrial environments, including wide temperature fluctuations, electrical noise, and vibration. Its advanced design simplifies system expansion and reduces maintenance efforts while maintaining system performance and safety integrity.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | AIP588 Electrical Transceiver RIO I/O Module |

| Module Type | Electrical Transceiver / Remote I/O |

| Input Type | Digital, Analog (configurable) |

| Output Type | Digital, Analog (configurable) |

| Communication Protocol | RIO (Reliable Input/Output), compatible with Yokogawa DCS |

| Isolation | Galvanic isolation between input/output and communication lines |

| Power Supply | 24 V DC ±10% |

| Power Consumption | ≤ 5 W |

| Operating Temperature Range | -20°C to 60°C |

| Storage Temperature Range | -40°C to 85°C |

| Humidity Tolerance | 5% to 95% RH, non-condensing |

| Response Time | ≤ 10 ms |

| Accuracy | ±0.1% of full scale (analog), logic-level verification (digital) |

| Dimensions (H × W × D) | 27 × 130 × 160 mm |

| Weight | 0.45 kg |

| Mounting | DIN rail or panel mounting |

| Certifications | CE, UL, IEC standards |

| LED Indicators | Power, Communication Status, I/O Status |

Product Applications

The AIP588 module is suitable for a variety of industrial and process control applications:

-

Integration of distributed field devices into the Yokogawa CENTUM VP DCS

-

Remote monitoring and control of analog and digital signals in critical processes

-

Signal transmission in harsh environments, such as chemical plants or refineries

-

Power generation monitoring systems for turbines, generators, and auxiliaries

-

Water and wastewater treatment plants requiring reliable remote I/O data acquisition

-

Infrastructure automation for large-scale industrial facilities

Product Advantages

-

High Reliability: Ensures consistent data communication even under high electrical noise or vibration conditions.

-

Flexible Configuration: Supports multiple I/O types with configurable channels for analog and digital signals.

-

Electrical Isolation: Protects sensitive control systems from voltage surges or ground loops.

-

Ease of Maintenance: Simple installation and quick replacement reduce system downtime.

-

Low Power Consumption: Efficient design minimizes power demand while maintaining performance.

-

Scalable Architecture: Facilitates expansion of control systems without redesigning the entire network.

-

Real-Time Performance: Fast response time ensures accurate and timely control actions.

Frequently Asked Questions (FAQ)

-

What types of digital signals can the AIP588 handle?

It supports both standard TTL-level and contact-type digital inputs and outputs. -

Can the module communicate with other vendors’ DCS systems?

The AIP588 uses Yokogawa RIO protocol; interoperability with third-party systems requires compatible protocol gateways. -

How does the module handle analog signal interference?

It features galvanic isolation and robust filtering to minimize noise and ensure accurate analog readings. -

What is the maximum cable length supported for RIO communication?

Up to 1 km using twisted-pair cabling, depending on the environment and data rate. -

How are I/O channels configured?

Configuration is performed through the CENTUM VP engineering software with user-defined mapping for each channel. -

Can the module be hot-swapped during operation?

No, the AIP588 requires power-down before replacement to prevent communication errors. -

What diagnostic features are available?

LED indicators for power, communication, and I/O status, along with software-based diagnostics in the DCS. -

How does the module respond to voltage surges?

Internal protection circuitry limits voltage spikes, protecting both module and system. -

Are there safety certifications for industrial use?

Yes, the module complies with CE, UL, and IEC standards suitable for industrial environments. -

What is the typical response time for a digital input to register in the DCS?

≤ 10 ms under normal operating conditions.

Related Models / Variants (Same Series or Functionally Similar)

| Model | Description |

|---|---|

| AIP587 | Electrical Transceiver RIO I/O Module (Digital Only) |

| AIP589 | Electrical Transceiver with Enhanced Analog Capability |

| AIP590 | RIO I/O Module with Integrated Diagnostics |

| AIP591 | High-Density Electrical Transceiver Module |

| AIP592 | RIO Module with Redundant Power Supply |

| AIP593 | Multi-Channel Electrical Transceiver Module |

Popular Models from Yokogawa

| Model | Description |

|---|---|

| AIP585 | Standard Electrical I/O Module |

| AIP586 | Digital Input/Output RIO Module |

| AIP580 | Analog Input Module |

| AIP581 | Analog Output Module |

| AIP582 | High-Speed I/O Module |

| AIP584 | Integrated Communication I/O Module |

Excellent PLC

Excellent PLC