| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

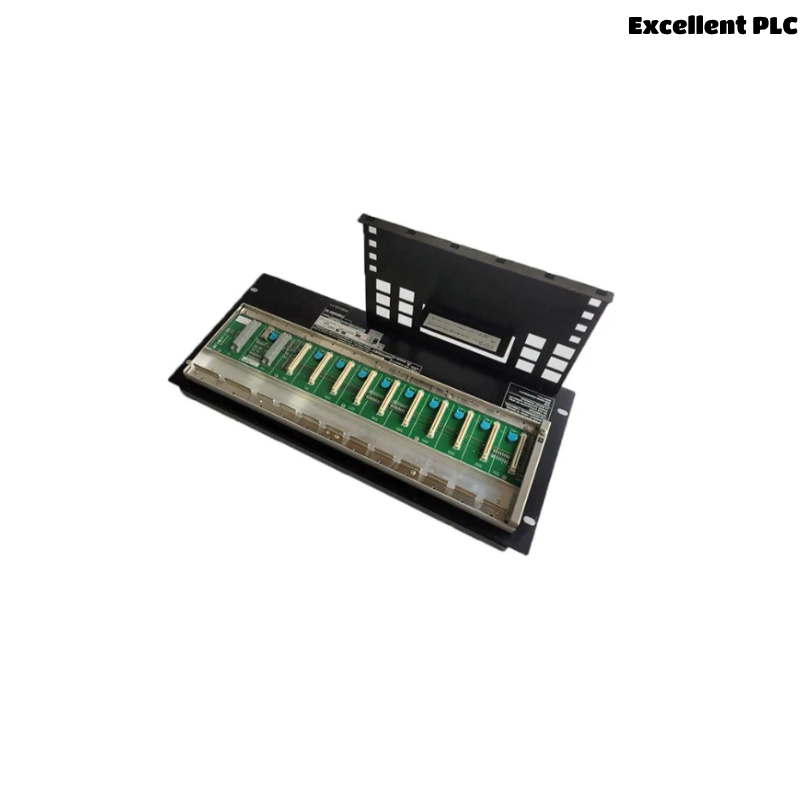

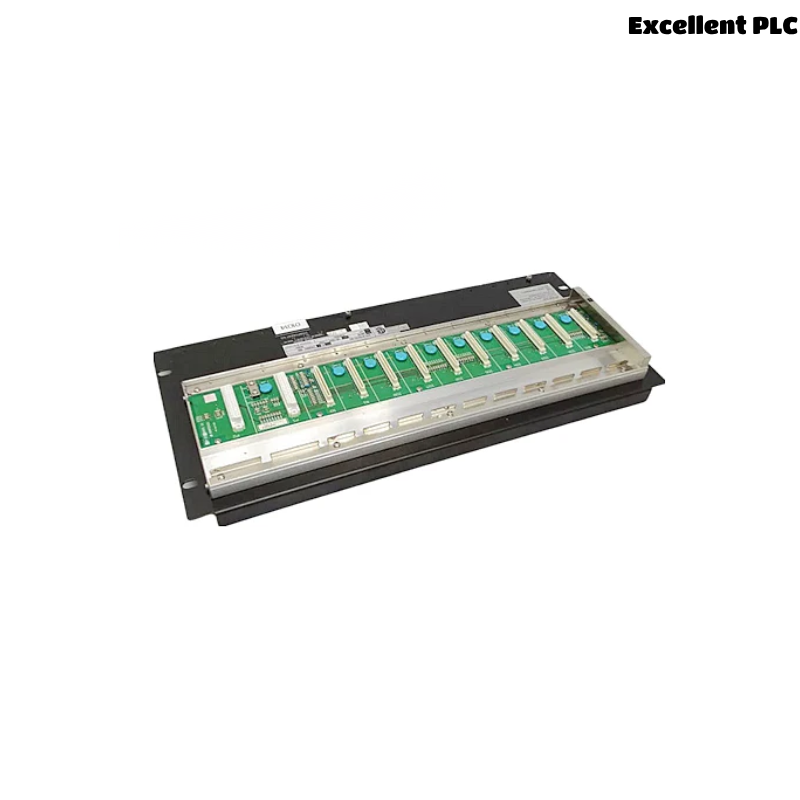

Yokogawa ANB10D Product Overview

The Yokogawa ANB10D is a high-performance I/O module designed for integration within the CENTUM CS 3000 and CENTUM VP distributed control systems (DCS). As part of Yokogawa’s field-proven automation platform, the ANB10D serves as a remote I/O base unit, connecting multiple I/O modules and enabling reliable communication with the system’s controllers. It is engineered to meet rigorous industrial requirements and is widely utilized in industries such as oil & gas, petrochemicals, energy, water treatment, and manufacturing.

The ANB10D supports a wide range of analog and digital I/O modules, ensuring scalability, redundancy, and flexibility. With durable design and compact architecture, the module helps streamline control room wiring while enhancing system responsiveness.

Technical Specifications of Yokogawa ANB10D

| Parameter | Specification |

|---|---|

| Model | ANB10D |

| Type | Remote I/O Base Unit |

| System Compatibility | CENTUM CS 3000 / CENTUM VP |

| Power Supply Voltage | 24 VDC (nominal), 18–32 VDC operating range |

| Power Consumption | Max. 7.5 W |

| Mounting Type | DIN rail or panel mounting |

| Number of I/O Slots | 10 slots |

| Communication Interface | Vnet/IP |

| Redundancy Support | Yes (via dual communication paths) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -40°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Dimensions | 482.6 × 221.5 ×205 mm |

| Weight | 10 kg |

| Certifications | CE, CSA, KC, UL |

Product Applications

The Yokogawa ANB10D is designed for industrial environments where robust and scalable remote I/O management is necessary. Common applications include:

-

Petrochemical plants: For managing process instrumentation and field devices remotely.

-

Power generation facilities: To support turbine and generator control systems.

-

Oil & gas refineries: For pipeline automation, compressor station control.

-

Water and wastewater treatment plants: Monitoring flow, pressure, and chemical dosing systems.

-

Pharmaceutical manufacturing: For precise process control and compliance tracking.

-

General manufacturing: Integration with automation machinery and sensors.

Key Advantages of the ANB10D

-

High Channel Density

The ANB10D supports up to 10 I/O modules in a single base, providing significant space and wiring savings. -

Modular and Scalable Architecture

Easily expandable to match growing plant requirements without changing system infrastructure. -

Reliable Communication via Vnet/IP

Ensures deterministic, high-speed, and redundant communication between controllers and I/O. -

Strong Environmental Tolerance

Suitable for harsh industrial conditions with wide temperature and humidity tolerances. -

Support for Redundant Systems

Enables high availability through dual communication paths and redundant module configuration. -

Easy Installation and Maintenance

Designed for fast module replacement and minimal system downtime. -

Compliance with Global Standards

Certified to meet CE, CSA, and other industrial standards, enhancing global applicability.

Frequently Asked Questions (FAQs)

Q1: What systems is the ANB10D compatible with?

A1: The ANB10D is fully compatible with Yokogawa CENTUM CS 3000 and CENTUM VP distributed control systems.

Q2: How many I/O modules can be installed on one ANB10D base unit?

A2: It supports up to 10 I/O modules on a single base.

Q3: Can I use ANB10D in high-vibration or dusty environments?

A3: Yes, its robust design and industrial-grade casing make it suitable for demanding environmental conditions.

Q4: Is hot-swapping of I/O modules supported?

A4: Yes, modules can be replaced without shutting down the system, minimizing downtime.

Q5: Does the ANB10D support redundant power supply configurations?

A5: Yes, it allows for redundant power input setups for enhanced reliability.

Q6: What type of communication protocol does it use?

A6: It uses Yokogawa’s Vnet/IP protocol for high-speed real-time control communication.

Q7: How does the ANB10D handle failures in I/O modules?

A7: The system detects faulty modules and can alert operators while maintaining system integrity.

Q8: Can the unit be mounted on both DIN rail and panels?

A8: Yes, the ANB10D supports both DIN rail and panel mount installation.

Q9: How is firmware updated on the ANB10D?

A9: Firmware updates are managed through the central system configuration tools provided by Yokogawa.

Q10: Is ANB10D suitable for use in SIL-rated systems?

A10: While it is highly reliable, users must verify compliance with specific SIL (Safety Integrity Level) requirements based on their application.

Recommended Same-Series / Related Models

-

Yokogawa ANB11D – Enhanced version with extended I/O support

-

Yokogawa ADV551-P00 – Analog input module for use with ANB base

-

Yokogawa ADV561-P00 – Analog output module compatible with ANB10D

-

Yokogawa AVV511-P00 – Digital input module

-

Yokogawa AVV521-P00 – Digital output module

-

Yokogawa AAI543-H00 – High-precision analog input module

Popular Yokogawa Models (with Specifications)

| Model | Function | Voltage | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| ANB10D | Remote I/O Base Unit | 24 VDC | 375 × 130 × 100 | 2.1 |

| ADV551-P00 | Analog Input Module | 24 VDC | 130 × 130 × 50 | 0.6 |

| ADV561-P00 | Analog Output Module | 24 VDC | 130 × 130 × 50 | 0.6 |

| AVV511-P00 | Digital Input Module | 24 VDC | 130 × 130 × 50 | 0.5 |

| AVV521-P00 | Digital Output Module | 24 VDC | 130 × 130 × 50 | 0.5 |

| AAI143-S00 | 16-Channel Analog Input | 24 VDC | 130 × 130 × 50 | 0.6 |

| AAI543-H00 | High Accuracy AI Module | 24 VDC | 130 × 130 × 50 | 0.7 |

| AAR181-S00 | Control Processor Module | 24 VDC | 150 × 130 × 60 | 1.2 |

Excellent PLC

Excellent PLC