| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

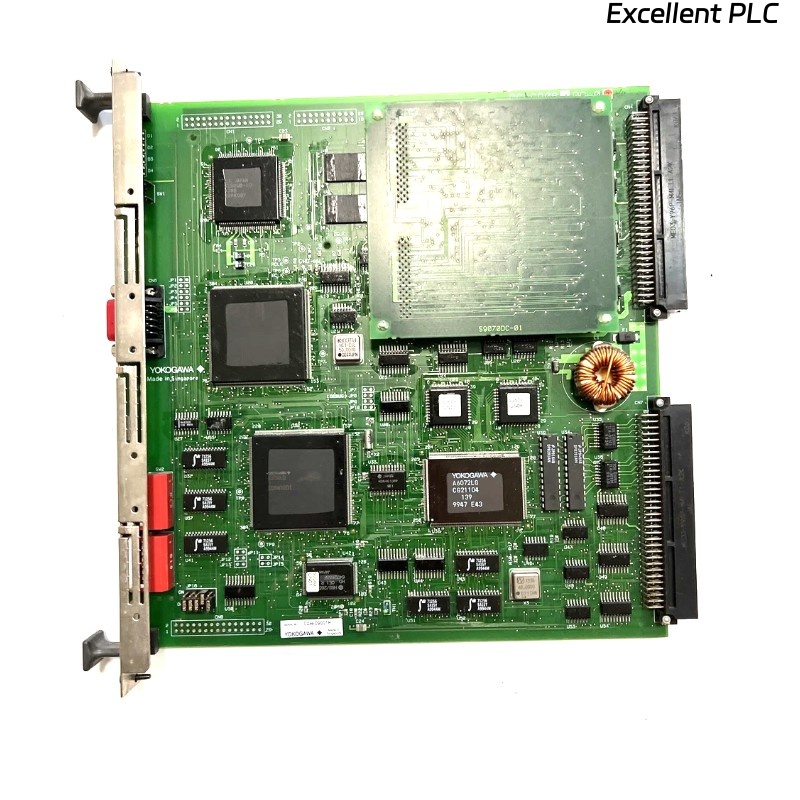

The Yokogawa CP701 FIELD CONTROL CPU is a versatile and reliable control unit designed for use in industrial automation systems. It acts as the central processing unit in a distributed control system (DCS), ensuring efficient communication between field devices and the control system. The CP701 is built to provide enhanced performance, scalability, and robust functionality for demanding applications across various industries, including manufacturing, energy, and infrastructure.

The CPU is designed for seamless integration with other Yokogawa control modules, allowing for easy expansion and adaptation to specific process needs. It supports a variety of protocols and communication standards, ensuring compatibility with modern industrial networks.

Product Specifications

Below are the key specifications of the Yokogawa CP701 FIELD CONTROL CPU:

| Specification | Detail |

|---|---|

| Model | CP701 FIELD CONTROL CPU |

| Dimensions | 320 x 210 x 60 mm |

| Weight | 2.5 kg |

| Input Voltage | 24 VDC ± 10% |

| Power Consumption | 25 W |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| CPU Speed | 1 GHz |

| Memory | 4 GB RAM, 16 GB Storage |

| Communication Ports | Ethernet, Serial, Fieldbus |

| Mounting | DIN Rail or Panel Mount |

| Certifications | CE, UL, FM |

Product Applications

The Yokogawa CP701 FIELD CONTROL CPU is utilized in a variety of applications, where its high performance and reliability are critical for maintaining system control. Its primary applications include:

-

Industrial Automation: Used in industries such as chemicals, petrochemicals, and pharmaceuticals for process automation and control.

-

Power Plants: Monitors and controls processes like turbine control, power distribution, and monitoring systems.

-

Manufacturing: For controlling production lines, robotics, and monitoring machine performance.

-

Infrastructure: In utilities for managing water treatment plants, sewage systems, and electrical grids.

-

Smart Buildings: Used in managing HVAC systems, lighting control, and security systems.

Product Advantages

-

High Processing Speed: The powerful CPU ensures quick data processing and response times for critical applications.

-

Scalability: The CP701 supports seamless expansion, making it ideal for projects of varying sizes.

-

Reliability: Built for continuous operation in harsh industrial environments with extended temperature ranges.

-

Flexible Communication: Multiple communication protocols are supported, including Ethernet and various Fieldbus standards, allowing for integration with a wide array of devices.

-

Easy Integration: The CP701 can easily integrate with other Yokogawa products, offering a unified solution for process control.

-

Energy Efficient: The system is designed to minimize power consumption while maintaining optimal performance.

FAQ

- Q1: What communication protocols are supported by the CP701?

- A1: The CP701 supports multiple communication protocols including Ethernet, Modbus, Profibus, and Yokogawa’s proprietary Fieldbus, ensuring compatibility with various industrial devices.

- Q2: Can the CP701 be used in hazardous environments?

- A2: Yes, the CP701 is built to withstand challenging industrial environments, with certifications for use in hazardous areas. However, specific certification details should be checked based on the environment’s risk level.

- Q3: How is the CP701 integrated into an existing control system?

- A3: The CP701 integrates into existing systems via standard communication protocols like Ethernet and Fieldbus. It is compatible with other Yokogawa products, ensuring smooth integration with minimal configuration.

- Q4: What is the maximum number of I/O modules that can be connected to the CP701?

- A4: The CP701 can handle up to 64 I/O modules, depending on the configuration and network setup. The exact number may vary based on the type of modules used.

- Q5: What is the expected data throughput of the CP701?

- A5: The CP701 has a data throughput capacity of up to 100 Mbps over Ethernet, providing fast communication between devices and the control system.

- Q6: Is the CP701 suitable for remote monitoring and control?

- A6: Yes, the CP701 supports remote monitoring and control through Ethernet and web-based interfaces, allowing operators to manage the system from anywhere.

- Q7: Does the CP701 support redundant configurations for increased reliability?

- A7: Yes, the CP701 supports redundant configurations for critical applications, ensuring system reliability in case of hardware failure.

- Q8: Can the CP701 handle real-time data processing?

- A8: Yes, the CP701 is designed for real-time data processing, making it ideal for applications that require immediate control responses.

- Q9: What is the recommended operating temperature range for the CP701?

- A9: The CP701 operates within a temperature range of -10°C to +60°C, making it suitable for most industrial environments.

- Q10: How is the CP701 mounted in an industrial setup?

- A10: The CP701 can be mounted on a DIN rail or directly onto a panel, providing flexibility in installation based on the user’s space and configuration requirements.

Related Models

| Model | Description |

|---|---|

| CP702 | An upgraded version of the CP701 with higher processing capacity and additional I/O support. |

| CP703 | A smaller variant for compact applications requiring fewer I/O points. |

| CP704 | A ruggedized version designed for extreme environments with enhanced protection. |

| CP705 | Offers expanded memory and faster processing for large-scale operations. |

| CP706 | Includes advanced diagnostic capabilities and supports more communication protocols. |

| CP707 | A budget-friendly option for small to medium-sized control systems. |

Popular Models from Yokogawa

| Model | Specifications |

|---|---|

| CS3000 | A comprehensive process control system with advanced control and optimization features. |

| STARDOM | A scalable DCS solution designed for continuous and batch processes. |

| FLX2 | A flexible and modular controller for varying process applications. |

| Exa | Advanced process control system focusing on precise measurement and control. |

| ProSafe | A safety instrumented system (SIS) with robust fault detection and redundancy. |

| PRM | Plant resource management system for effective asset and maintenance management. |

Excellent PLC

Excellent PLC