| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

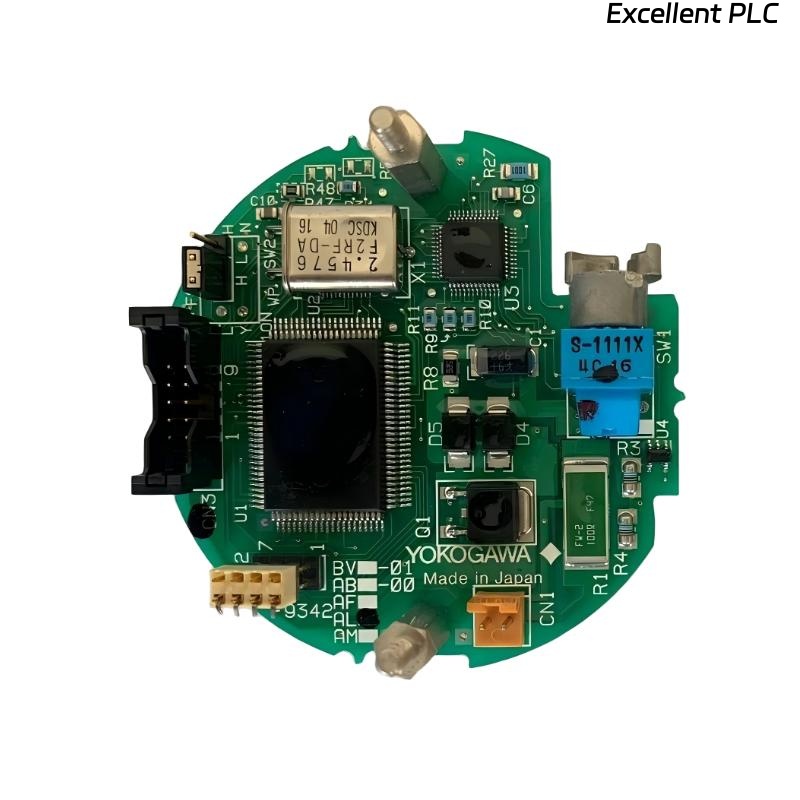

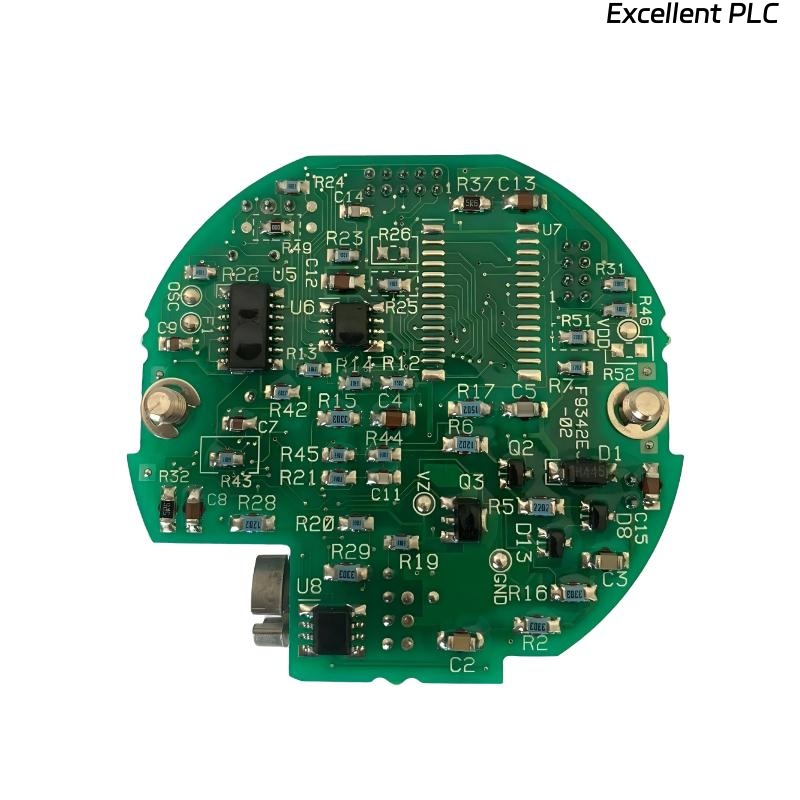

Product Introduction

The Yokogawa F9342AL Pressure Transmitter CPU Assembly is a high-performance central processing module designed specifically for smart pressure transmitters operating under the HART communication protocol. This CPU assembly serves as the brain of the transmitter, managing all internal signal conversions, communication processing, diagnostic functions, and digital data transmission between the sensing element and external control systems.

Engineered with Yokogawa’s advanced microprocessor technology, the F9342AL module ensures fast signal processing, high computational accuracy, and stable operation under challenging industrial conditions. The embedded firmware is optimized for HART version compatibility, enabling reliable analog + digital hybrid communication across a wide range of distributed control systems (DCS) and field communication devices.

Constructed with a robust circuit design, industrial-grade components, and strong EMC protection, the F9342AL guarantees continuous, precise measurement data transmission and efficient diagnostic capability in process automation environments. It is an essential part of Yokogawa’s digital pressure transmitter family, ensuring superior reliability, compatibility, and maintainability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | F9342AL |

| Product Type | Pressure Transmitter CPU Assembly |

| Supported Protocol | HART Protocol (Version 5/7 Compatible) |

| Microprocessor Type | 32-bit embedded microcontroller |

| Memory | 128 KB Flash ROM, 8 KB RAM |

| ADC Resolution | 16-bit high-precision analog-to-digital converter |

| Signal Processing Speed | 1 ms cycle |

| Communication Interface | 4–20 mA + HART digital signal |

| Supply Voltage | 10.5–45 V DC |

| Power Consumption | < 3.5 W |

| Isolation | Galvanic isolation between input/output |

| Self-Diagnostics | Continuous internal fault detection |

| Operating Temperature | -40 °C to +85 °C |

| Humidity Range | 0–95% RH (non-condensing) |

| Dimensions (L × W × H) | 85 × 65 × 22 mm |

| Weight | 0.2 kg |

| Compliance | CE, RoHS, EMC Directive |

| Mounting Type | Internal assembly (pressure transmitter mainboard) |

| Protection | ESD, surge, and reverse polarity protection |

Applications

The F9342AL CPU Assembly is utilized as the control and communication core in Yokogawa’s HART-compatible pressure transmitters and similar field instruments. It ensures the accurate processing of analog signals from pressure sensors and conversion into digital communication data compliant with industrial automation standards.

Common application areas include:

-

Process pressure transmitters for oil, gas, and chemical plants.

-

Flow and level transmitters using differential pressure measurement.

-

Steam and power systems requiring high signal integrity and diagnostics.

-

Pharmaceutical and food industry instrumentation with strict communication standards.

-

Control loop interfaces in DCS or PLC environments for analog/digital data integration.

-

Plant safety and monitoring systems where HART protocol is essential for diagnostics.

Through stable data processing and consistent HART communication, the F9342AL ensures dependable field-to-control room integration and contributes to predictive maintenance and operational efficiency.

Advantages

The Yokogawa F9342AL Pressure Transmitter CPU Assembly delivers multiple design and performance advantages:

-

High Processing Precision: Advanced 32-bit microprocessor architecture ensures precise analog signal conversion.

-

Enhanced HART Communication: Fully supports HART version 5 and 7 protocols with reliable hybrid signal transmission.

-

Fast Response: Optimized algorithm enables a rapid 1 ms processing cycle for real-time data updates.

-

Integrated Self-Diagnostics: Detects CPU faults, signal deviations, and calibration errors automatically.

-

Stable Operation in Harsh Environments: Designed for wide temperature and humidity ranges with ESD protection.

-

Low Power Design: Consumes less than 3.5 W, ensuring energy efficiency and thermal stability.

-

Robust Electrical Protection: Includes galvanic isolation and surge resistance for industrial reliability.

-

High Compatibility: Works seamlessly with Yokogawa’s transmitters and third-party HART systems.

-

Compact and Lightweight: Small form factor allows easy installation and modular replacement.

-

Long-Term Reliability: Built with industrial-grade electronic components for sustained accuracy and durability.

FAQ

-

What is the communication protocol supported by the F9342AL CPU Assembly?

It supports the HART protocol (version 5 and 7), enabling both analog and digital communication. -

What type of microprocessor is used in this module?

A high-speed 32-bit embedded microcontroller optimized for real-time signal processing. -

How does the CPU assembly handle analog-to-digital conversion?

It utilizes a 16-bit high-precision ADC to convert sensor signals into digital data for transmission. -

Is galvanic isolation implemented in the design?

Yes, full galvanic isolation is provided between input, output, and communication circuits. -

What diagnostic features are built into the F9342AL?

It supports continuous self-diagnostics, including CPU integrity checks and communication fault detection. -

Can it be used with older transmitter models?

Yes, it is backward compatible with earlier Yokogawa HART transmitter designs using the same communication protocol. -

What is the signal processing speed of the unit?

The CPU processes input signals in approximately 1 millisecond per cycle. -

What are the EMC and safety protections integrated into the module?

It includes ESD protection, surge suppression, and reverse polarity protection for stable operation. -

How is the firmware updated or configured?

Firmware can be updated via the transmitter’s service port or configuration interface using Yokogawa tools. -

Does it require calibration after replacement?

Yes, calibration is recommended after installation to ensure precise alignment with the sensing module.

Related Models (Same Series or Compatible)

| Model | Description |

|---|---|

| F9342AK | CPU Assembly for analog pressure transmitters (non-HART) |

| F9342AL | CPU Assembly for HART protocol version |

| F9342AM | CPU Assembly with enhanced diagnostics and memory capacity |

| F9342AN | CPU Board for FOUNDATION Fieldbus compatible transmitters |

| F9342AP | Digital CPU Module with PROFIBUS support |

| F9342AQ | Compact CPU Assembly for smart transmitter upgrade kits |

Popular Models (Same Brand)

| Model | Description |

|---|---|

| EJA110E | Differential Pressure Transmitter with HART protocol |

| EJX310A | High-accuracy pressure transmitter with digital output |

| EJA530A | Gauge Pressure Transmitter for industrial process measurement |

| F9340GP | Gasket for transmitter sealing (fluorinated rubber, degreased) |

| F9341JP | O-Ring for transmitter cover assembly |

| EJA210E | Differential pressure transmitter for liquid level measurement |

Excellent PLC

Excellent PLC