| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

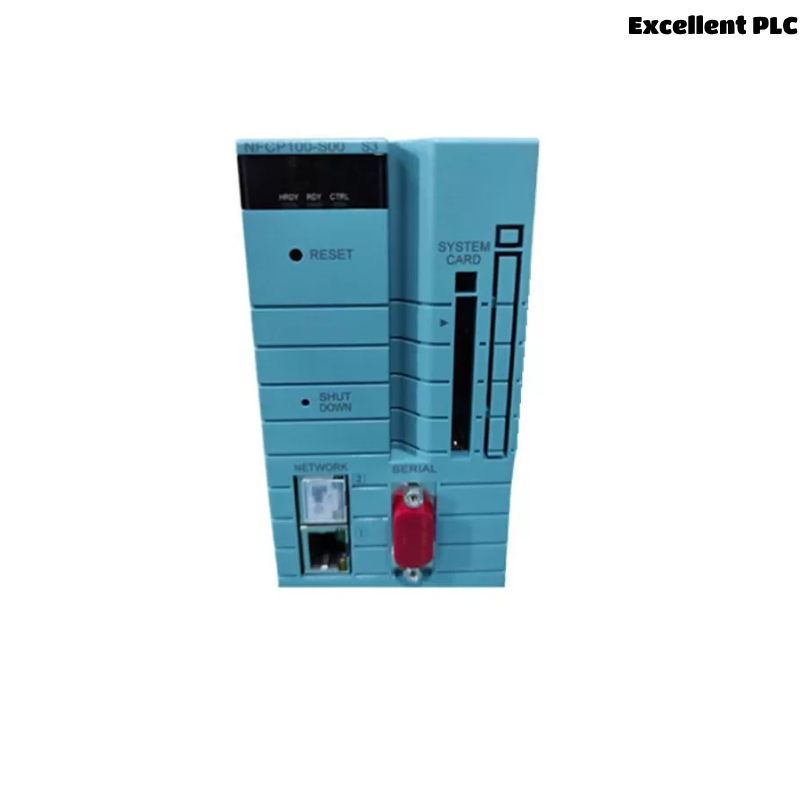

The Yokogawa NFCP501 is a robust and highly versatile controller module developed by Yokogawa, designed specifically for process automation, critical plant applications, and industrial control environments. As part of Yokogawa’s proven field control range, the NFCP501 provides reliable and precise management of complex systems. Its design reflects Yokogawa’s decades-long expertise in automation, featuring high-quality engineering and practical adaptability to diverse industrial requirements.

The NFCP501 is crafted to seamlessly integrate into large-scale distributed control systems (DCS), maintaining consistent operation even under demanding conditions. By leveraging modern communication protocols and advanced hardware, it ensures stable, real-time control, which is vital for industries like oil & gas, power generation, chemical processing, and more.

Product Parameters

| Parameter | Details |

|---|---|

| Model | Yokogawa NFCP501 |

| Dimensions | 65.8 x 130 x 149.3 mm |

| Weight | 0.9 kg |

| Input Voltage | DC 24V nominal (range: 19.2V to 28.8V) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Mounting | Rack-mounted / panel-mounted |

| Communication Interfaces | Ethernet, RS-485, Fieldbus |

| Processing Performance | High-speed 32-bit processor |

| Redundancy Support | Supported (dual module configuration) |

| Compliance | CE, RoHS, UL |

Product Applications

The NFCP501 is engineered for use in a wide array of industrial settings, where precision, reliability, and system stability are non-negotiable:

-

Distributed Control Systems (DCS) in petrochemical, power, and water treatment facilities

-

Batch processing control in food and beverage industries

-

SCADA integration for remote monitoring and control

-

Turbine and generator management in power plants

-

Critical alarm and event monitoring

-

Plant data acquisition and historical data archiving

Its modularity and communication flexibility make it suitable both for greenfield installations and upgrades to existing plants seeking higher performance without full replacement.

Product Advantages

-

Reliability: Built for continuous operation in harsh industrial environments, minimizing downtime.

-

Modularity: Easy to integrate into Yokogawa’s CENTUM VP and other systems, supporting scalable architectures.

-

Redundancy: Dual-module support enhances system resilience and operational safety.

-

Advanced Communication: Compatibility with modern protocols ensures seamless integration with other devices and systems.

-

Ease of Maintenance: Modular design simplifies replacement and service without full system shutdown.

-

Precision Control: Ensures stable, real-time control for critical processes, improving product quality and operational efficiency.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of the Yokogawa NFCP501?

A1: When operated under recommended conditions, the NFCP501 can reliably serve for over 5 years, thanks to its industrial-grade build.

Q2: Can it be used in high-vibration environments?

A2: Yes, it is designed with vibration-resistant mounting and robust internal construction, suitable for most industrial settings.

Q3: Is the NFCP501 compatible with third-party SCADA systems?

A3: Absolutely; it supports widely adopted protocols like Ethernet and RS-485, making third-party integration straightforward.

Q4: Does it support hot-swapping?

A4: Yes, in redundant configurations, you can replace a faulty module without interrupting system operation.

Q5: Is software included with the module?

A5: Configuration and monitoring software tools from Yokogawa are available separately, designed specifically to work with NFCP501.

Q6: How often should it be calibrated?

A6: Typically, calibration is recommended every 2-3 years, but this depends on usage intensity and plant requirements.

Q7: What is the power consumption?

A7: The typical power consumption is around 10-15W under normal operating conditions.

Q8: Can it operate in outdoor conditions?

A8: The NFCP501 is intended for indoor control room environments; if installed outdoors, it should be housed in an IP-rated enclosure.

Q9: Does it have built-in diagnostics?

A9: Yes, it features comprehensive self-diagnostic functions to alert maintenance staff of irregularities.

Q10: Is remote firmware update supported?

A10: Yes, firmware can be updated remotely using Yokogawa’s dedicated tools, ensuring systems stay up-to-date.

Recommended Related Models (Same series / related)

-

Yokogawa NFCP502

-

Yokogawa NFCP503

-

Yokogawa NFCP201

-

Yokogawa NFCP301

-

Yokogawa NFCP601

-

Yokogawa NFCP701

These models vary mainly in processing power, I/O capabilities, or specialized functions, making them complementary for diverse plant setups.

Popular Models from the Same Brand (with specifications)

| Model | Dimensions (W×H×D) | Weight | Voltage | Key Use |

|---|---|---|---|---|

| NFCP501 | 130×100×250 mm | 2.3 kg | DC 24V | General control module |

| NFCP502 | 130×100×260 mm | 2.5 kg | DC 24V | Enhanced I/O support |

| NFCP503 | 130×110×250 mm | 2.6 kg | DC 24V | High-speed processing |

| ALR111-S00 | 100×80×220 mm | 1.8 kg | DC 12/24V | Alarm relay module |

| AIP827-2 | 140×100×260 mm | 2.7 kg | DC 24V | Analog input module |

| ADV551-P00 | 120×90×240 mm | 2.0 kg | DC 24V | Digital output module |

| AIP502 | 130×100×240 mm | 2.1 kg | DC 24V | Compact input processor |

| NFAR300 | 150×120×270 mm | 3.0 kg | DC 24V | Advanced field controller |

Excellent PLC

Excellent PLC