| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

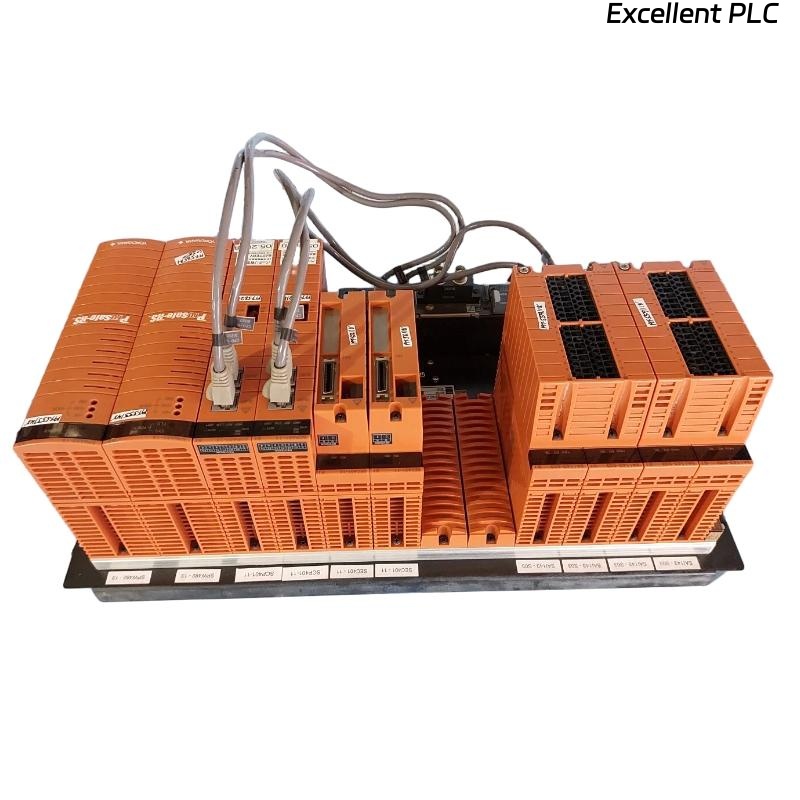

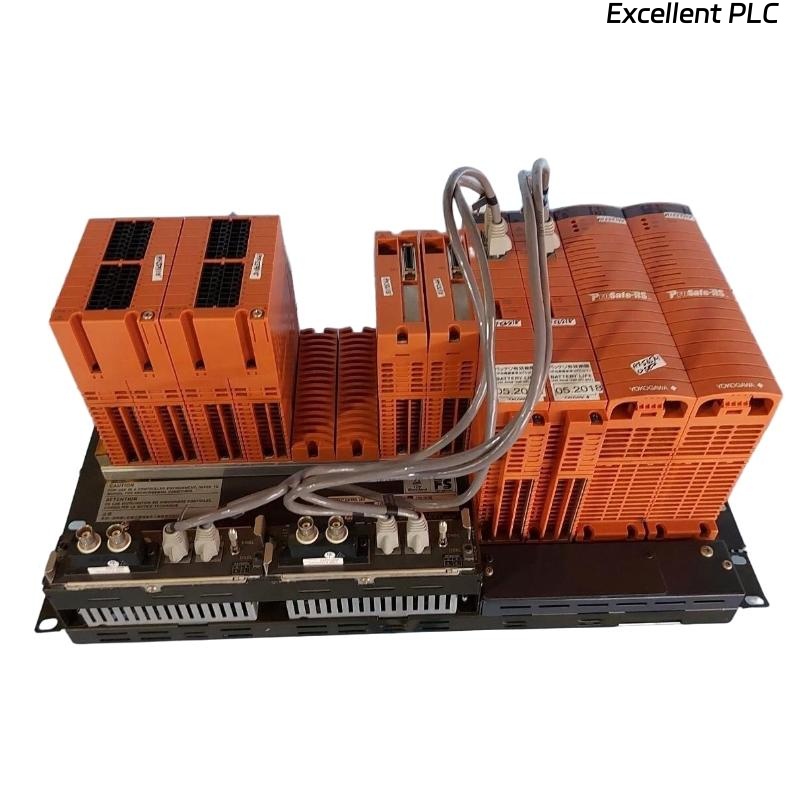

The Yokogawa SSC10D-F Safety Control Unit is an advanced controller within the ProSafe-RS safety instrumented system (SIS). It is designed to provide high levels of operational safety, system reliability, and seamless integration with process automation platforms. The “D” designation in the SSC10D-F indicates a dual redundant CPU architecture, which ensures continuous operation even in the event of hardware failures. This redundancy makes the SSC10D-F an essential choice for industries where safety and uninterrupted operation are critical, such as oil and gas, petrochemicals, power generation, and chemical plants.

By combining safety and automation into one platform, the SSC10D-F not only ensures compliance with stringent safety standards but also reduces lifecycle costs and simplifies system maintenance.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | SSC10D-F |

| Product Type | Safety Control Unit (SIS Module) |

| System Platform | ProSafe-RS |

| CPU Architecture | Dual Redundant (High Availability) |

| Input Channels | Digital and Analog (configurable) |

| Output Channels | Digital and Analog (configurable) |

| Safety Integrity Level (SIL) | SIL3 (IEC 61508 certified) |

| Communication Protocols | Vnet/IP, SafetyNet |

| Power Supply | 24 V DC |

| Operating Temperature | -10°C to 55°C |

| Storage Temperature | -20°C to 70°C |

| Humidity Tolerance | 5% to 95% RH (non-condensing) |

| EMC Compliance | IEC/EN standards |

| Dimensions | 482.6 x 266 x 88.1 mm |

| Weight | 13 kg |

| Certifications | CE, ATEX, IECEx, TÜV |

Applications

The SSC10D-F is widely used in safety-critical process automation and monitoring applications:

-

Oil & Gas: Emergency shutdown systems (ESD), fire and gas systems (F&G), and high-integrity pressure protection systems (HIPPS).

-

Petrochemical Plants: Process safety control for flammable or hazardous chemical environments.

-

Power Generation: Steam turbine safety, boiler protection, and generator interlock systems.

-

Chemical Plants: Mitigation of unsafe chemical reactions and containment of hazardous processes.

-

Water Treatment Facilities: Protection and monitoring of critical pumping and treatment processes.

-

General Industry: Unified safety and process control integration with Yokogawa’s DCS.

Advantages

-

Dual Redundant CPUs: Ensures continuous operation and fault tolerance without process interruption.

-

Certified Safety Compliance: Achieves SIL3 certification under IEC 61508, meeting global safety standards.

-

Seamless Integration: Fully compatible with Yokogawa’s CENTUM VP and other DCS platforms.

-

High Reliability: Built-in diagnostic features allow early fault detection and predictive maintenance.

-

Scalable Architecture: Supports both small-scale and large-scale plant safety applications.

-

Strong Communication Capabilities: Vnet/IP and SafetyNet ensure fast, secure, and reliable data exchange.

-

Rugged Design: Operates reliably across industrial temperature and humidity ranges.

-

Global Certification: ATEX and IECEx certified for hazardous locations.

FAQ

-

Which safety standard does the SSC10D-F comply with?

It complies with IEC 61508 and is certified for SIL3 safety applications. -

What distinguishes the SSC10D-F from the SSC10S-F model?

The SSC10D-F uses a dual redundant CPU design, enhancing system availability and fault tolerance. -

What communication protocols are supported by the SSC10D-F?

It supports Vnet/IP and SafetyNet for reliable and secure data transmission. -

Does the SSC10D-F allow hot-swapping of modules?

Yes, modules can be replaced while the system remains operational, improving maintainability. -

How does the SSC10D-F manage diagnostics?

It includes continuous self-checks and diagnostic monitoring for hardware, software, and communication errors. -

What I/O configurations are available for this unit?

It supports both digital and analog input/output channels, configurable depending on the application. -

Can the SSC10D-F operate in hazardous industrial environments?

Yes, it is ATEX and IECEx certified for use in hazardous zones. -

What is the power requirement for this unit?

The SSC10D-F operates with a standard 24 V DC power supply. -

How fast is the safety response time of the SSC10D-F?

It delivers rapid safety responses suitable for emergency shutdown and protective interlock applications. -

Is the SSC10D-F compatible with Yokogawa DCS systems?

Yes, it integrates seamlessly with Yokogawa’s CENTUM VP and other control platforms for unified process and safety control.

Related Models (Same Series or Related)

| Model Number | Type | Key Feature |

|---|---|---|

| SSC10S-F | Safety Control Unit | Single CPU architecture, SIL3 compliant |

| SSC20S-F | Safety Control Unit | Expanded input/output capacity |

| SSC50S-F | Safety Controller | High-speed processing for safety applications |

| SSC60S-F | Safety Control Unit | Enhanced diagnostics with advanced logging |

| SSC100S-F | Safety Control Unit | Large-scale plant safety system integration |

| SSC200S-F | Safety Controller | Advanced redundancy and scalability |

Popular Models (Same Brand)

| Model Number | Type | Key Feature |

|---|---|---|

| FIO110 | Field I/O Module | Flexible input/output expansion |

| CP451-10 | Controller Module | High-performance process control CPU |

| ALR121 | Alarm Module | Reliable alarm and alert management |

| PW482-10 | Power Supply Module | Stable 24 V DC power for Yokogawa systems |

| AIP827-10 | Analog Input Module | High-accuracy analog signal acquisition |

| SAI143-H50 | Safety Analog Input Module | Certified SIL input for safety applications |

Excellent PLC

Excellent PLC