| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

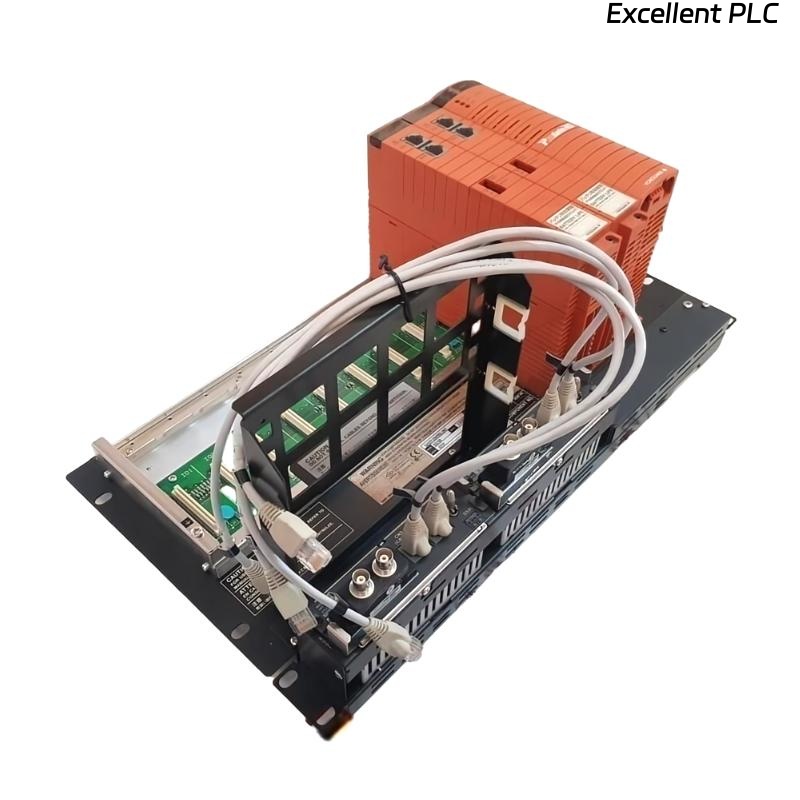

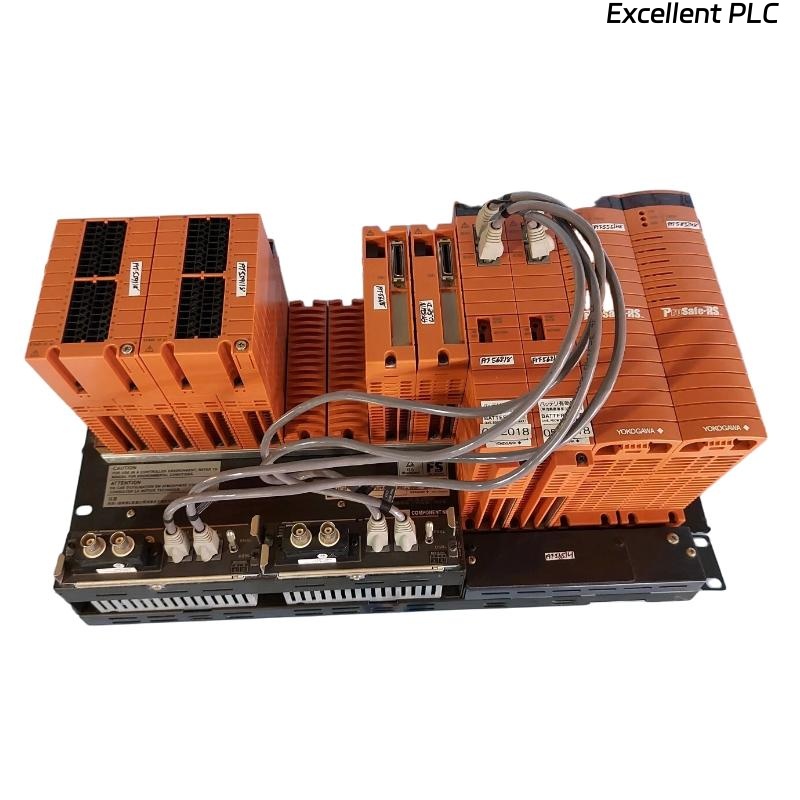

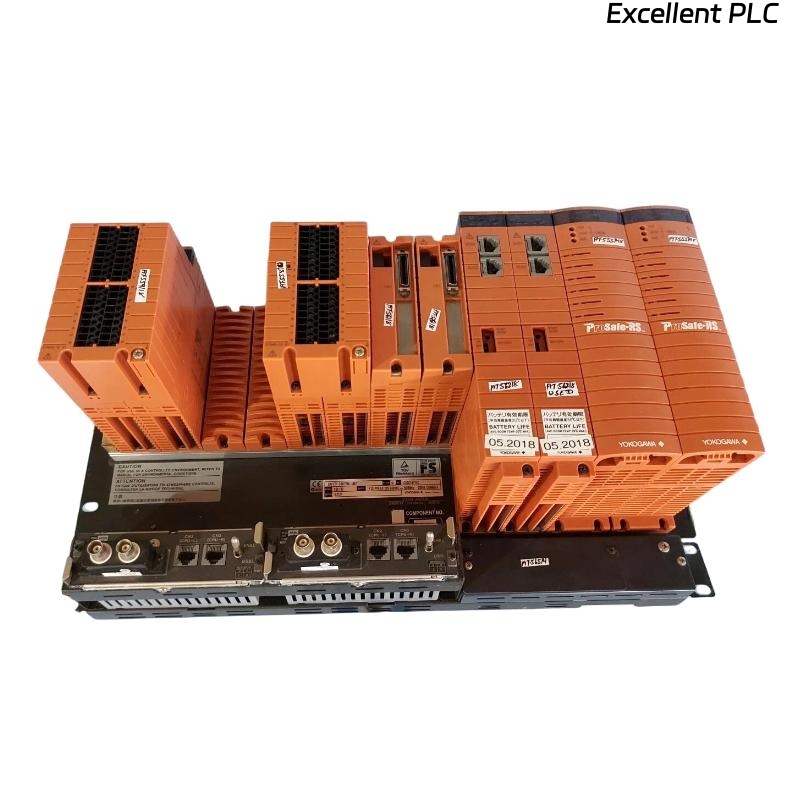

The Yokogawa SSC10D-S2111 Duplexed Safety Control Unit is a high-integrity, fault-tolerant safety controller developed for use in Yokogawa’s ProSafe-RS Safety Instrumented System (SIS). Designed to meet the most stringent safety and reliability standards, the SSC10D-S2111 is responsible for executing safety logic, managing redundant safety I/O operations, and ensuring continuous plant operation even in the event of hardware or communication faults.

This controller integrates seamlessly with CENTUM VP and other Yokogawa distributed control systems, forming a unified architecture for both process control and safety management. It employs a dual-redundant architecture, where two processors operate in parallel to continuously cross-check logic execution, guaranteeing safe operation even if one processor fails.

The SSC10D-S2111 provides superior diagnostics, self-checking mechanisms, and deterministic performance. It is widely used in industries where process safety, reliability, and availability are paramount — including oil & gas, petrochemical, power generation, and refining sectors.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | Yokogawa SSC10D-S2111 Duplexed Safety Control Unit |

| Manufacturer | Yokogawa Electric Corporation |

| Product Type | Safety Control Processor (SIS Controller) |

| System Compatibility | ProSafe-RS Safety Instrumented System |

| Processor Configuration | Dual redundant (1oo2D architecture) |

| CPU Type | 32-bit RISC processor |

| Execution Cycle | Deterministic, configurable scan time 10–100 ms |

| Memory Capacity | 32 MB Flash, 64 MB RAM |

| Logic Handling | IEC 61131-3 compliant function block programming |

| Communication Interface | Safety communication bus (Vnet/IP), redundant Ethernet |

| Redundancy | Processor, power supply, communication, and I/O redundancy supported |

| Input/Output Capacity | Up to 4,000 safety I/O points (expandable) |

| Safety Integrity Level (SIL) | Certified for SIL3 according to IEC 61508 |

| Response Time | <50 ms typical for safety-critical logic |

| Power Supply Voltage | 24 VDC nominal (range 19.2–28.8 VDC) |

| Power Consumption | Approx. 25 W (dual module operation) |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -20°C to +70°C |

| Humidity | 10%–90% RH non-condensing |

| Diagnostics | Self-diagnosis, online test, watchdog timer, communication monitoring |

| Communication Protocols | Vnet/IP (redundant), Modbus TCP, Modbus RTU |

| Mounting Type | Rack-mounted (with baseplate) |

| Certifications | TÜV, ATEX, CE, CSA, UL, IECEx |

| Dimensions (W × H × D) | 482.6 x 266 x 88.1 mm |

| Weight | 13 kg |

| Maintenance | Hot-swap capable; online firmware upgrade |

| Programming Tool | SCS Logic Designer (part of ProSafe-RS environment) |

| Compliance Standards | IEC 61508, IEC 61511, EN 50156, ISO 13849-1 |

Product Applications

The SSC10D-S2111 Duplexed Safety Control Unit is engineered to provide dependable safety control and process shutdown capabilities across various industries. Its duplex architecture ensures continuous plant protection and system integrity.

-

Oil & Gas Production – Used in emergency shutdown (ESD), fire and gas (F&G), and high-integrity pressure protection systems (HIPPS).

-

Petrochemical & Refining – Provides safe interlocks for critical equipment such as compressors, reactors, and furnaces.

-

Power Generation – Controls turbine overspeed protection, boiler safety, and auxiliary system monitoring.

-

Chemical Processing – Ensures safety interlocks, reactor pressure control, and hazardous gas containment.

-

Offshore Platforms – Manages safety shutdown and fire detection integration in offshore drilling and production facilities.

-

Pipeline Control Systems – Implements leak detection, isolation, and pressure control mechanisms.

The SSC10D-S2111 delivers precise and immediate response to hazardous conditions, ensuring personnel and equipment protection while maintaining operational continuity.

Product Advantages

-

High Safety Integrity (SIL3) – Meets IEC 61508 standards, guaranteeing reliable safety performance.

-

Duplexed Redundancy – Two processors operate in parallel (1oo2D), allowing fault tolerance without system interruption.

-

Unified Architecture – Integrates seamlessly with CENTUM VP for both control and safety, reducing engineering workload.

-

Online Maintenance – Modules can be replaced or updated while the system remains operational.

-

Advanced Diagnostics – Continuous health monitoring and self-diagnostics minimize unplanned shutdowns.

-

Flexible Configuration – Scalable to thousands of I/O points and adaptable to diverse plant structures.

-

Deterministic Performance – Real-time control and predictable execution cycle ensure precise safety logic operation.

-

Robust Communication – Dual-redundant Vnet/IP provides high-speed and reliable data transfer.

-

Low Lifecycle Cost – Modular design and reduced engineering complexity result in lower maintenance expenses.

-

Proven Field Reliability – Extensively deployed in critical safety systems worldwide.

FAQ

-

What safety standard does the SSC10D-S2111 comply with?

It complies with IEC 61508 and IEC 61511, certified for Safety Integrity Level 3 (SIL3). -

How does the duplex architecture function?

It uses a 1oo2D configuration where two processors run identical logic simultaneously and continuously compare results to ensure safe operation. -

Can the SSC10D-S2111 communicate with non-Yokogawa systems?

Yes, it supports open communication protocols such as Modbus TCP and Modbus RTU for integration with third-party systems. -

Does the controller support online software modification?

Yes, the system allows online configuration changes under controlled safety conditions. -

What happens if one CPU fails?

If one processor fails, the other continues operation seamlessly, maintaining full system functionality without interruption. -

Is redundancy available for communication networks?

Yes, the SSC10D-S2111 provides dual-redundant Vnet/IP communication to ensure continuous data transmission. -

What diagnostic features are included?

It features continuous self-check, watchdog timers, communication monitoring, and module-level fault detection. -

Can firmware be updated while in operation?

Yes, firmware updates can be performed online without system shutdown, depending on configuration. -

What is the typical response time for safety actions?

The controller executes safety logic within approximately 50 milliseconds. -

Is the SSC10D-S2111 compatible with ProSafe-RS configuration tools?

Yes, it is fully compatible with Yokogawa’s SCS Logic Designer and Safety Control Station (SCS) software environment.

Related Models from the Same Series

| Model | Description | Architecture | SIL Rating | Key Feature |

|---|---|---|---|---|

| SSC10D-S2110 | Standard Safety Control Unit | Single | SIL3 | Compact single-processor configuration |

| SSC50D-S2211 | High-performance Duplex Safety Controller | Duplex | SIL3 | Enhanced I/O capacity |

| SSC60D-S3111 | Advanced Safety Processor | Duplex | SIL3 | Faster scan time and larger memory |

| SCS10D-S2111 | Safety Control Station | Duplex | SIL3 | Centralized logic execution |

| SSC30D-S1111 | Modular Safety Control Unit | Duplex | SIL2 | Designed for small safety applications |

| SCC10D-S2011 | Communication Controller | Duplex | SIL3 | Redundant communication interface for SIS networks |

Popular Yokogawa Models

| Model | Product Type | System Compatibility | Key Feature |

|---|---|---|---|

| AAM50 | Analog Input Module | CENTUM VP | 16-bit precision signal processing |

| ADV151 | Digital Output Module | ProSafe-RS | Safety-rated discrete output channels |

| CP451-10 | Processor Module | CENTUM CS 3000 | Redundant control processor unit |

| PDM104 | Power Supply Module | DCS / SIS | Dual redundant 24VDC supply system |

| SB401-10 | Communication Module | Field Control Unit | High-speed Vnet/IP redundancy |

| AV55D | Digital Input Module | CENTUM VP | 32-channel high-density input capability |

Excellent PLC

Excellent PLC