| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

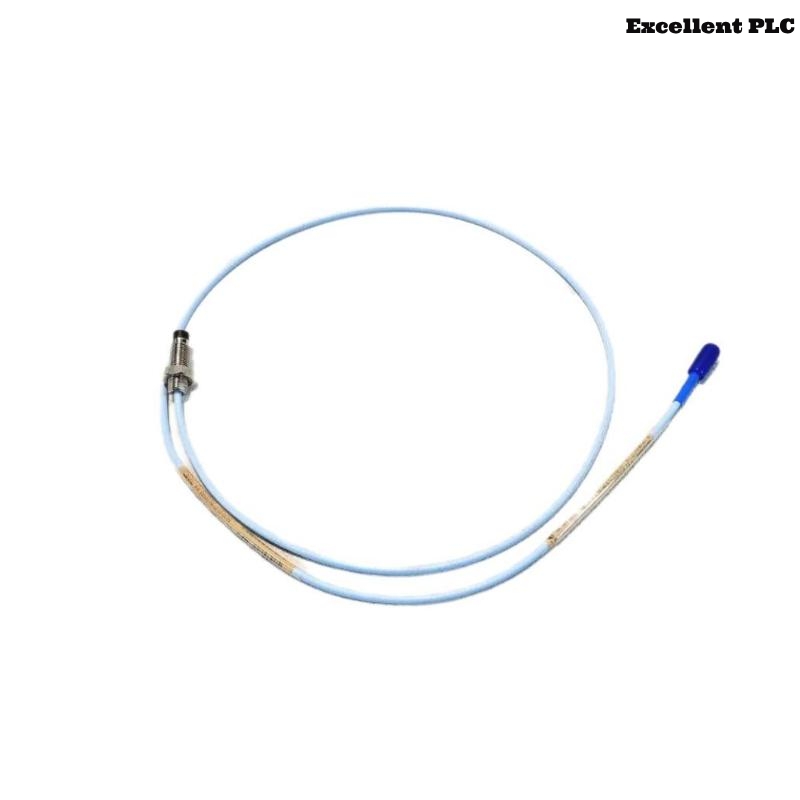

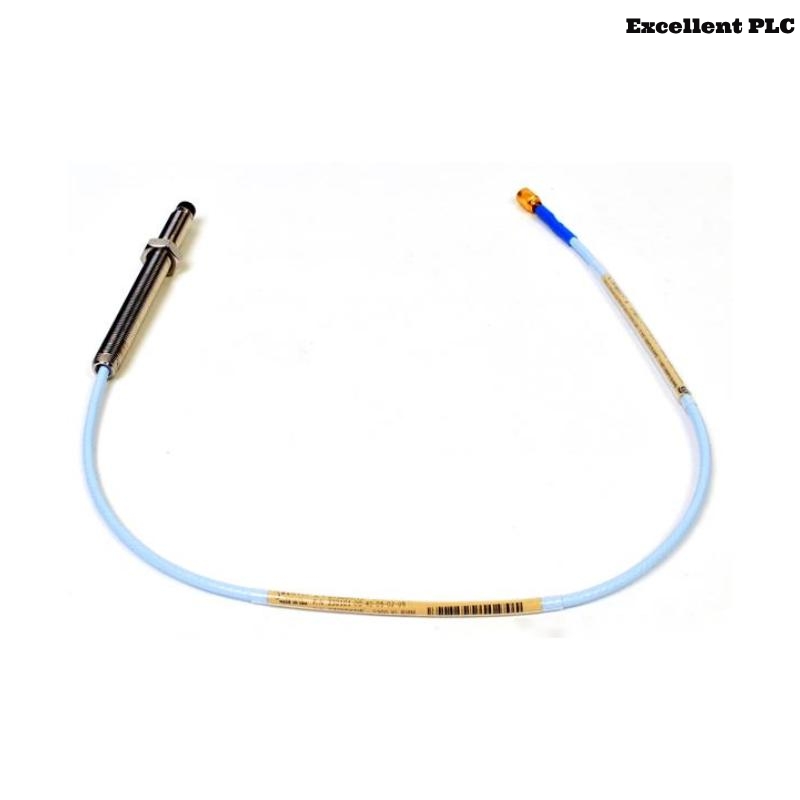

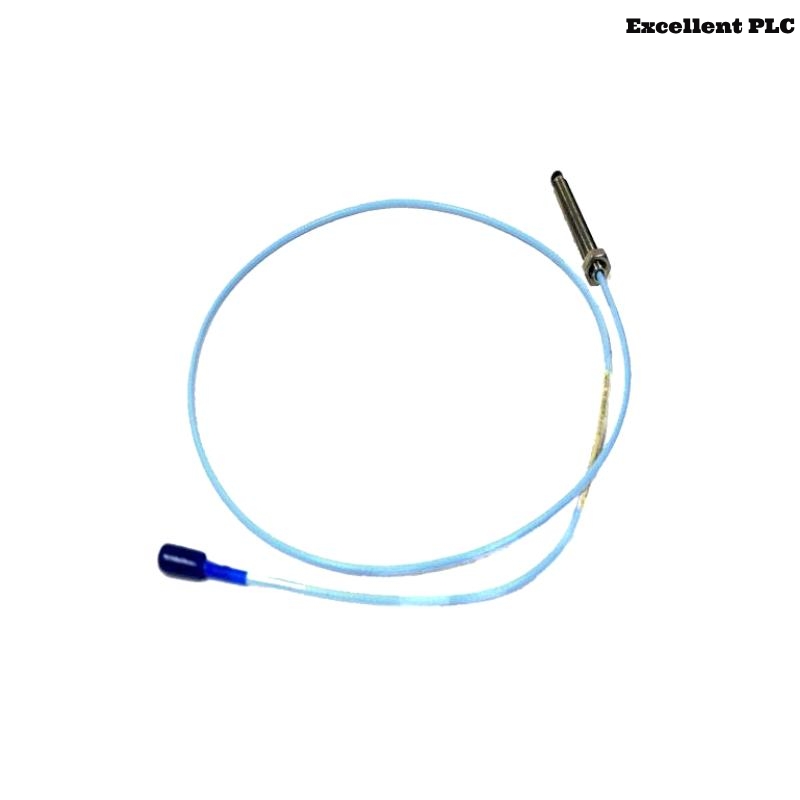

The Bently Nevada 330101-00-43-10-02-05 is a robust and high-precision proximity probe from the widely recognized 3300 XL 8mm Proximity Transducer System. Designed for use in demanding industrial environments, this probe is engineered for accurate, non-contact measurement of shaft vibration and position. As part of the 3300 XL system, it works with a matching extension cable and proximitor sensor to provide continuous, reliable monitoring of rotating machinery.

This specific model, with a 1.0 meter probe cable and a reverse mount unarmored configuration, is designed for applications where space constraints or mounting accessibility require a flexible installation solution. Backed by decades of Bently Nevada experience, the 330101-00-43-10-02-05 remains a standard of reliability in predictive maintenance and condition monitoring programs.

Product Specifications:

| Parameter | Specification |

|---|---|

| Part Number | 330101-00-43-10-02-05 |

| System Type | 3300 XL 8mm Proximity Transducer System |

| Technology | Eddy Current, Non-contact Measurement |

| Probe Tip Diameter | 8 mm |

| Total Length | 1.0 meter |

| Thread Size | 3/8-24 UNF-2A (reverse mount) |

| Mounting Style | Reverse Mount, Unarmored |

| Connector Type | ClickLoc Stainless Steel Connector |

| Output Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Sensing Range | 2 mm (80 mils) |

| Linear Range | 0.5 mm to 2.0 mm (20 to 80 mils) |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Material | Stainless Steel body |

| Ingress Protection | IP65 with proper sealing |

| Power Supply | Powered via proximitor (not direct powered) |

| Weight | 0.323 kg |

Product Applications:

The 330101-00-43-10-02-05 is widely implemented in rotating machinery condition monitoring systems across industries such as oil & gas, power generation, refining, and manufacturing. It plays a vital role in protecting high-value assets by detecting early-stage mechanical issues.

Typical applications include:

-

Steam and Gas Turbines – Measuring radial and axial shaft displacement to prevent catastrophic failures.

-

Centrifugal Compressors – Monitoring rotor vibration to detect imbalance, misalignment, or bearing issues.

-

Industrial Pumps – Detecting shaft deflection and ensuring proper mechanical seal function.

-

Large Electric Motors and Generators – Measuring shaft movement to avoid rotor-to-stator contact.

-

Gearboxes – Identifying abnormal gear mesh vibration and looseness.

-

Fans and Blowers – Ensuring balance and proper alignment under dynamic load conditions.

Product Advantages:

-

High Measurement Accuracy: Maintains consistent output over a wide temperature and vibration range.

-

Reliable Performance: Designed to deliver reliable proximity measurements even in hazardous and high-speed machinery.

-

Non-contact Operation: Eliminates mechanical wear, extending operational life and reducing maintenance.

-

Wide Compatibility: Integrates seamlessly with other Bently Nevada 3300 XL components and condition monitoring systems.

-

Rugged Build Quality: Built with industrial-grade stainless steel for long-term operation in tough environments.

-

Flexible Installation: Reverse mount configuration and specific cable lengths allow precise placement in constrained setups.

-

Secure Connection: Features a ClickLoc connector that ensures a secure and vibration-resistant electrical connection.

-

Field-Proven Design: Trusted by global industries for critical equipment protection and diagnostics.

-

Minimized Downtime: Enables predictive maintenance strategies that reduce unscheduled outages.

-

Globally Supported: Supported by Bently Nevada’s global service network and extensive application knowledge.

Frequently Asked Questions (FAQ):

-

What does the model number 330101-00-43-10-02-05 signify?

-

It denotes a specific 3300 XL 8mm probe with a 43-inch cable, reverse mount, and ClickLoc connector.

-

-

Can this probe be used without an extension cable or proximitor?

-

No, it must be used with a matched extension cable and a proximitor to function correctly.

-

-

Is the probe sensitive to electromagnetic interference (EMI)?

-

It is designed with shielding to minimize the impact of EMI in industrial environments.

-

-

What is the difference between forward mount and reverse mount probes?

-

Reverse mount allows installation from behind the mounting surface, useful in space-limited setups.

-

-

What is the expected service life of this probe?

-

With proper installation and environment, it can last for years with minimal drift.

-

-

Can the cable length be modified?

-

Factory cable length is fixed; other standard lengths are available by ordering different part numbers.

-

-

What environmental protection does the probe have?

-

It offers IP65 protection when properly installed with sealing.

-

-

Is this model compatible with legacy 7200 series proximitor systems?

-

No, it is designed specifically for the 3300 XL system and is not backward-compatible.

-

-

What types of faults can this probe detect?

-

Misalignment, imbalance, bearing wear, mechanical looseness, and rotor rub.

-

-

How is calibration performed for this system?

-

Calibration is typically factory-set; field calibration involves system alignment with the proximitor and extension cable.

Related Models (Same Series or Function Group):

| Model Number | Cable Length | Mount Style | Connector Type | Application |

|---|---|---|---|---|

| 330101-00-40-10-02-05 | 40 inches | Reverse Mount | ClickLoc | General shaft vibration |

| 330101-00-50-10-02-00 | 50 inches | Forward Mount | Standard | Mid-length machinery setups |

| 330101-00-60-10-02-00 | 60 inches | Forward Mount | ClickLoc | Large compressors |

| 330101-00-80-10-02-00 | 80 inches | Reverse Mount | ClickLoc | Remote mounting situations |

| 330104-00-05-10-02-00 | 5 meters | Armored Probe | Standard | Harsh environments |

| 330103-00-08-10-02-00 | 8 meters | Extension Cable | N/A | Signal path completion |

Popular Bently Nevada Models (Same Brand):

| Model Number | Type | Function | Key Feature |

|---|---|---|---|

| 3500/42M | Proximitor/Seismic Monitor | Vibration & Position Monitoring | Multiple channel support, configurable |

| 3500/25 | Keyphasor Module | Speed and phase measurement | Essential for rotor speed detection |

| 3500/22M | Transient Data Interface | System communication module | Ethernet-based, high-speed |

| 3300/16-13-01-01-00-00-00 | Proximitor Monitor | Legacy proximity signal processing | Rack-mount compatible |

| 330103-00-08-10-02-00 | 8mm Extension Cable | Probe system connectivity | Matches XL series probes |

| 7200-50 Series | Proximity Transducer System | Position & vibration measurement | Legacy system, robust performance |

Excellent PLC

Excellent PLC