| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

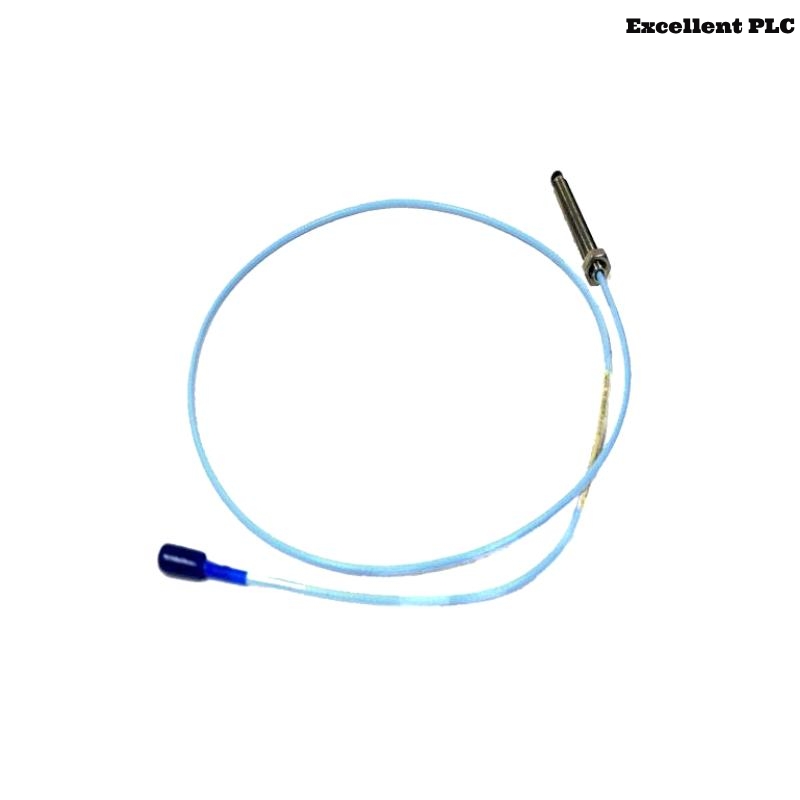

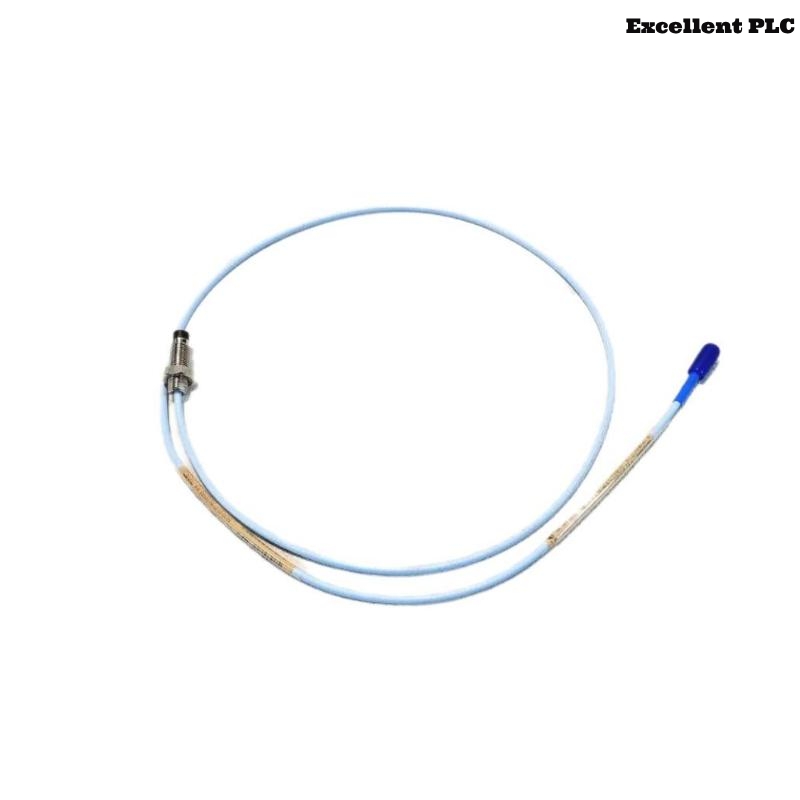

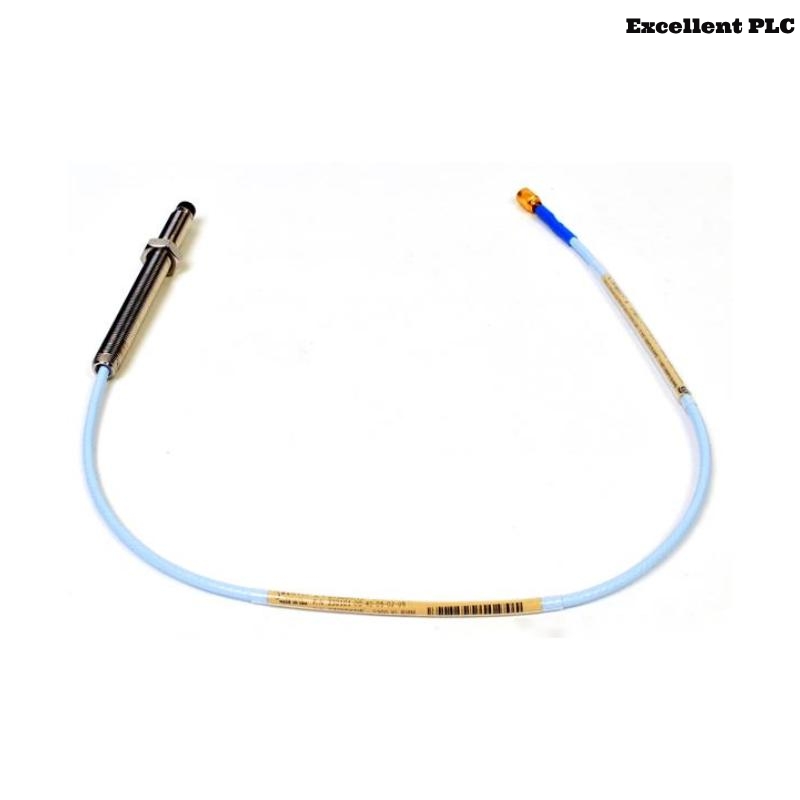

The Bently Nevada 330101-00-56-10-02-00 is part of the highly reliable and widely adopted 3300 XL 8mm Proximity Transducer System by Bently Nevada. Designed to provide precise, non-contact vibration and displacement measurements, this probe system is built to operate effectively in the most demanding industrial environments.

This specific probe assembly consists of a proximitor sensor, extension cable, and probe tip, which together form a critical part of condition monitoring and machinery protection systems. With a robust design and exceptional measurement stability, the 3300 XL 8mm probe is engineered for compatibility with API 670 standards and is trusted by engineers worldwide for rotating machinery applications such as turbines, compressors, motors, and pumps.

Product Specifications

| Parameter | Value |

|---|---|

| Product Model | 330101-00-56-10-02-00 |

| Series | 3300 XL 8mm Proximity Transducer System |

| Tip Diameter | 8 mm |

| Thread Type | 3/8-24 UNF-2A |

| Total Length | 1.0 meter |

| Connector Type | Miniature coaxial connector |

| Target Material | AISI 4140 steel |

| System Length | 9 meters (combined probe and extension cable length) |

| Operating Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Sensitivity | 200 mV/mil (7.87 mV/μm) ±5% |

| Linear Range | 0.25 mm to 2.0 mm (10 mils to 80 mils) |

| Non-Linearity | Within ±0.25 V over the linear range |

| Frequency Response | 0 Hz to 10 kHz |

| Case Material | AISI 303 stainless steel |

| Weight | 0.323 kg |

| Mounting Thread | 3/8-24 UNF |

| Sealing | Hermetically sealed (IP68 rating for industrial use) |

Applications

The Bently Nevada 330101-00-56-10-02-00 proximity probe is used extensively in the following industries and applications:

-

Turbomachinery Monitoring: For steam, gas, and hydro turbines.

-

Compressors: Measurement of shaft vibration and axial thrust.

-

Motors and Generators: Non-contact detection of shaft movement and runout.

-

Pumps and Fans: For machinery health and failure prediction.

-

Gearboxes: To detect abnormal vibration due to gear wear or misalignment.

-

Industrial Process Plants: Especially in petrochemical, oil & gas, and power generation sectors.

-

API 670 Machinery Protection Compliance: Fully compatible with relevant specifications.

Product Advantages

-

High Reliability: Built for long-term use in harsh industrial environments.

-

API 670 Compliant: Ensures compatibility with global machinery protection standards.

-

Stable Sensitivity: 200 mV/mil provides consistent and precise measurement accuracy.

-

Robust Mechanical Design: Stainless steel body and hermetically sealed assembly ensure durability.

-

Wide Operating Range: Functions effectively across extreme temperature conditions.

-

Ease of Integration: Works seamlessly with 3300 XL systems and legacy Bently Nevada monitors.

-

Industry-Proven Performance: Trusted across thousands of industrial applications globally.

-

Minimal Signal Drift: Ensures accurate long-term monitoring without frequent recalibration.

Frequently Asked Questions (FAQ)

-

What is the exact measurement range of the 330101-00-56-10-02-00 probe?

It measures shaft vibration and position in the range of 0.25 mm to 2.0 mm. -

Is this proximity probe suitable for API 670 machinery protection systems?

Yes, it meets the API 670 requirements for shaft vibration and displacement monitoring. -

What is the system length supported by this model?

It supports a system length of 9 meters when combined with the appropriate extension cable and proximitor. -

Can the probe operate in extreme temperatures?

Yes, its operating temperature range is from -51°C to +177°C. -

What kind of machinery is it typically installed on?

It is commonly used in turbines, compressors, motors, pumps, and other rotating machines. -

Is the product hermetically sealed?

Yes, the probe is hermetically sealed and rated IP68 for use in harsh environments. -

What is the thread type on the probe?

The mounting thread is 3/8-24 UNF-2A, a common industrial standard. -

Is it compatible with other Bently Nevada systems?

Yes, it is fully compatible with 3300 XL systems and legacy Bently Nevada monitors. -

What material is the probe tip made from?

The target material for calibration is AISI 4140 steel, while the probe body is AISI 303 stainless steel. -

Can it be used in explosive or hazardous environments?

With appropriate system certification and installation, it can be used in hazardous area classifications.

Related Models (Same Series)

| Model | Description | Tip Size | System Length | Thread Type |

|---|---|---|---|---|

| 330101-00-40-10-02-00 | 3300 XL 8mm Probe, 40” length | 8 mm | 9 m | 3/8-24 UNF |

| 330101-00-80-10-02-00 | 3300 XL 8mm Probe, 80” length | 8 mm | 9 m | 3/8-24 UNF |

| 330104-00-05-10-02-00 | 3300 XL 11 mm Probe, shorter reach | 11 mm | 5 m | M10 x 1 |

| 330105-02-12-10-02-00 | 3300 XL NSv Probe, narrow tip for tight spaces | 5 mm | 5 m | 1/4-28 UNF |

| 330106-05-30-10-02-00 | 3300 XL 25 mm Long-Range Probe | 25 mm | 9 m | 3/8-24 UNF |

| 3300XL-VTPT | Velocity Transducer Probe for radial vibration | – | – | Industrial Mounting |

Popular Models from Bently Nevada (Same Brand)

| Model | Function | Application | Output Type |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | 3500 monitoring system | Ethernet |

| 3500/42M | Proximitor Monitor | Vibration/Position Monitoring | Buffered/Relay |

| 3500/32M | Relay Module | Protection/Shutdown Relay | Relay |

| 3500/15E | Power Supply Module | Power distribution in rack | AC/DC Input |

| 330180-91-05 | Extension Cable for 3300 XL Probes | Extension of proximity systems | Coaxial |

| 330730-040-00-00 | Proximitor Sensor | Works with 3300 XL probes | Voltage (200 mV/mil) |

Excellent PLC

Excellent PLC