| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

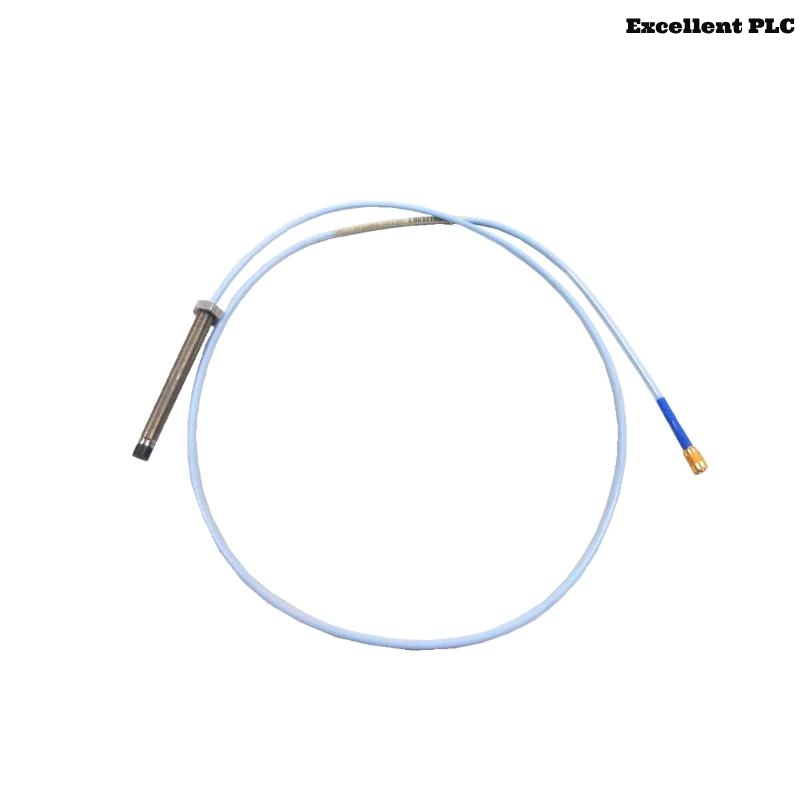

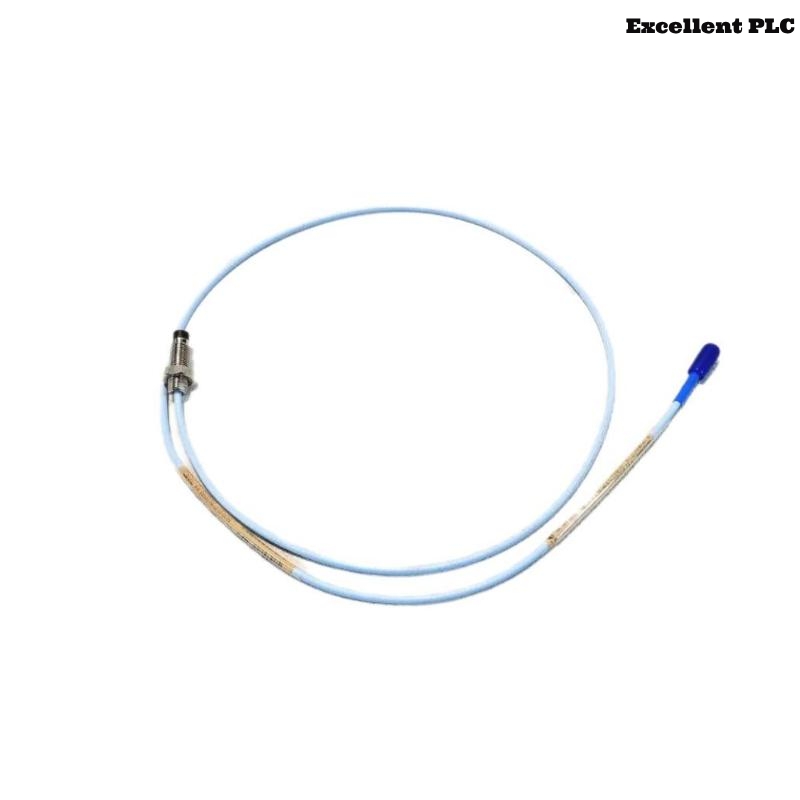

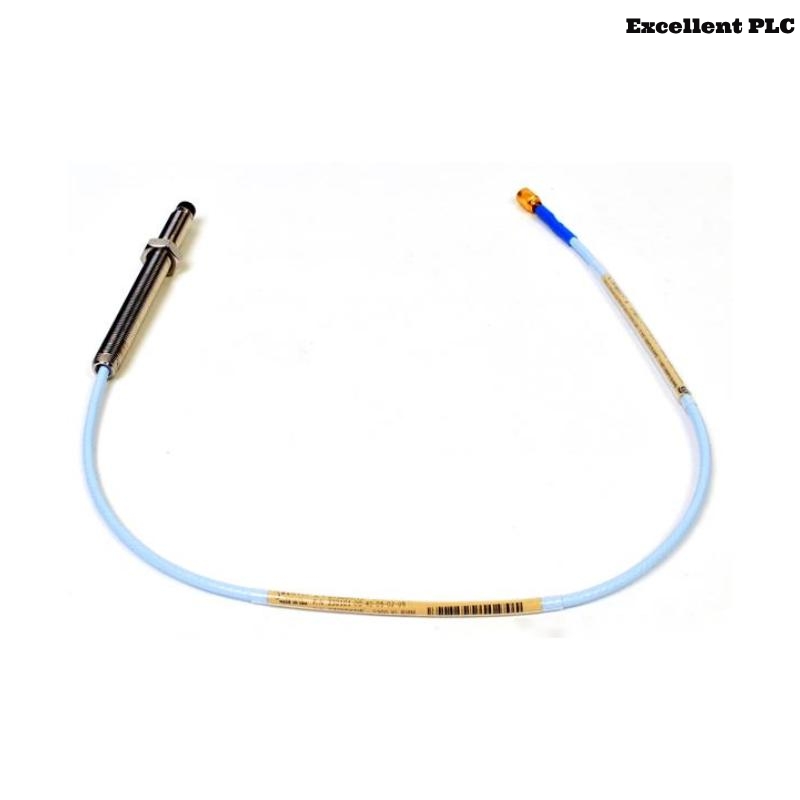

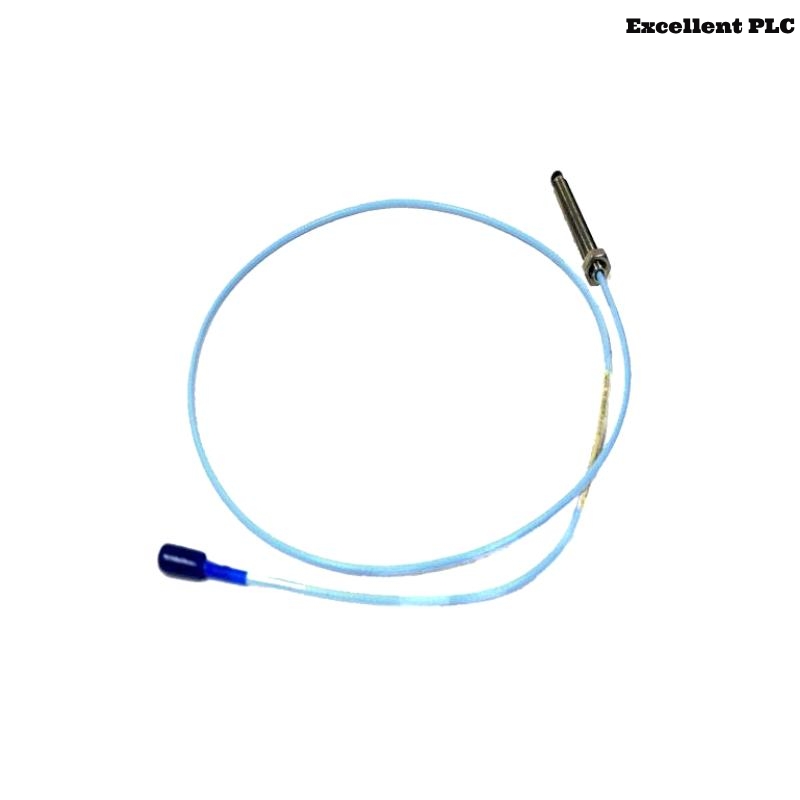

The Bently Nevada 330101-00-50-10-02-00 is a high-performance proximity probe designed as part of the 3300 XL 8mm Proximity Transducer System, developed by Bently Nevada, a trusted name in industrial condition monitoring and vibration detection. This probe is primarily used for non-contact displacement measurements and vibration monitoring of rotating machinery.

The 3300 XL series is renowned for its exceptional reliability in demanding industrial environments, such as power generation, petrochemical, and oil & gas sectors. This specific model—330101-00-50-10-02-00—features a 1.0 meter Total Length extension cable, and a connector protector designed for enhanced field durability and signal integrity.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | 330101-00-50-10-02-00 |

| Series | 3300 XL 8mm Proximity Probes |

| Probe Tip Diameter | 8 mm |

| Total Length | 1.0 meter |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linear Range | 80 mils (2 mm) |

| Frequency Range | 0 to 10 kHz |

| Probe Material | AISI 303 Stainless Steel |

| Cable Armor | Optional flexible stainless steel conduit |

| Connector Type | Miniature coaxial connector |

| Operating Temperature Range | -35°C to +177°C |

| Storage Temperature | -51°C to +177°C |

| Environmental Sealing | IP65 (with connector protector installed) |

| Vibration Limit | 10 g pk, 58–500 Hz |

| Shock Limit | 1000 g, 1 ms |

| Mounting Thread | 1/4-28 UNF-2A |

| Weight | 0.323 kg |

| System Compatibility | Compatible with 3300 XL Proximitor and 3300 monitoring systems |

Product Applications

The 330101-00-50-10-02-00 proximity probe is ideally suited for the following applications:

-

Shaft vibration and displacement monitoring in rotating machines

-

Thrust position measurements in steam and gas turbines

-

Axial position monitoring in compressors and pumps

-

Condition monitoring in gearboxes and centrifugal machines

-

Integration into API 670 compliant systems

-

Continuous machinery protection in hazardous and high-temperature environments

These probes are frequently deployed in oil refineries, power plants, chemical facilities, and water treatment stations.

Product Advantages

-

Industry-Standard Performance: Offers consistent and reliable 200 mV/mil sensitivity in line with API 670.

-

High Environmental Tolerance: Functions reliably in high temperature, high vibration, and hazardous industrial environments.

-

Robust Construction: Stainless steel design ensures resistance to corrosion and wear.

-

Field Replaceability: The modular design allows quick replacement without recalibration.

-

Superior Signal Integrity: Shielded coaxial cabling minimizes electrical noise and signal degradation.

-

Compatibility: Fully compatible with legacy and new Bently Nevada monitoring systems.

-

Long-Term Stability: Proven performance over extended durations with minimal drift.

Frequently Asked Questions (FAQ)

-

What is the sensing range of the 330101-00-50-10-02-00 probe?

→ The typical linear sensing range is 80 mils (2 mm). -

Can this proximity probe be used in hazardous environments?

→ Yes, it is often used in hazardous areas when paired with appropriate monitoring systems. -

Is this model compliant with API 670?

→ Yes, it conforms to API 670 standards when used as part of the 3300 XL system. -

Does this probe support extension cable connections?

→ Yes, this model includes a 10 ft extension cable in its configuration. -

What kind of connector does it use?

→ A miniature coaxial connector is used for secure, high-fidelity signal transfer. -

What is the temperature tolerance of the probe?

→ Operating range is -35°C to +177°C, and storage range is -51°C to +177°C. -

How should the probe be mounted?

→ It uses a 1/4-28 UNF-2A threaded mount and requires proper alignment for accurate measurements. -

Can this model work with non-Bently Nevada systems?

→ While optimized for Bently Nevada monitors, it may be adapted to other systems with signal conditioning. -

What materials is the probe made of?

→ It is constructed using AISI 303 stainless steel for durability and corrosion resistance. -

What maintenance is required for this probe?

→ Minimal maintenance; periodic visual inspection and cleaning of the tip is recommended.

Related Models (Same Series or Compatible)

| Model Number | Description |

|---|---|

| 330101-00-30-10-02-00 | 3300 XL 8mm probe with 30 ft cable and 10 ft extension |

| 330101-00-80-10-02-00 | 3300 XL 8mm probe with 80 ft cable and 10 ft extension |

| 330104-00-12-10-02-00 | 3300 XL 11 mm probe, 12 ft cable, high-temperature version |

| 330130-040-00-00 | Extension cable for 3300 XL probes, 40 ft |

| 330180-91-05 | 3300 XL Proximitor Sensor, 5 m cable, DIN rail mount |

| 330105-02-12-10-02-00 | Reverse Mount 8mm probe, 12 ft cable, 10 ft extension |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3500/22M | Key interface module for Bently Nevada 3500 system |

| 3500/42M | Proximitor Seismic Monitor module |

| 3300 XL 8mm | Complete proximity transducer system with 8mm sensing head |

| 3500/15 | Power supply module for 3500 series |

| 3500/60 | Temperature Monitor module for process applications |

| 3500/25 | Keyphasor module for speed/phase measurements |

Excellent PLC

Excellent PLC