| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

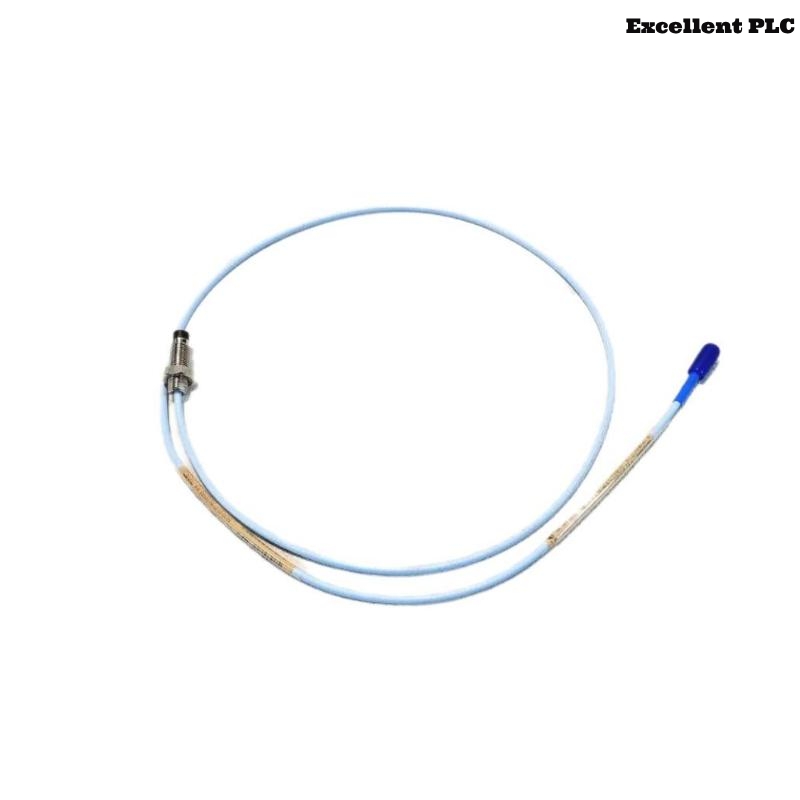

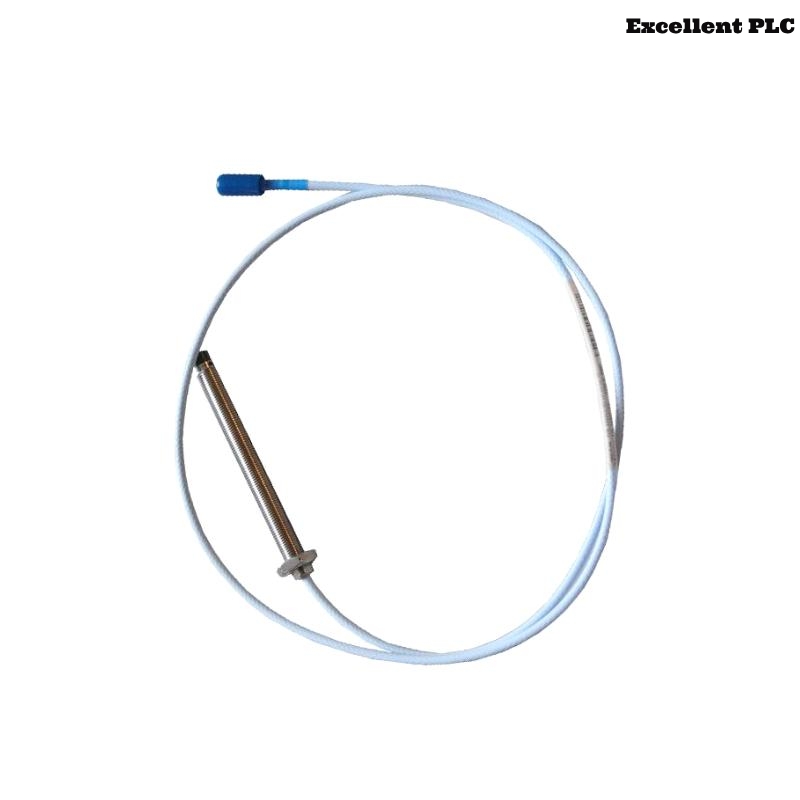

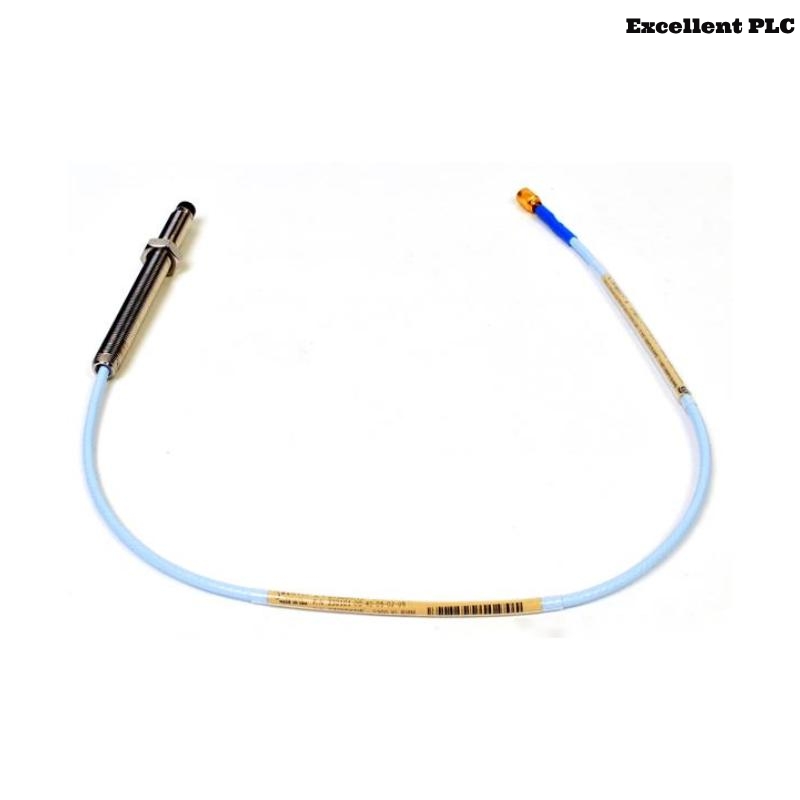

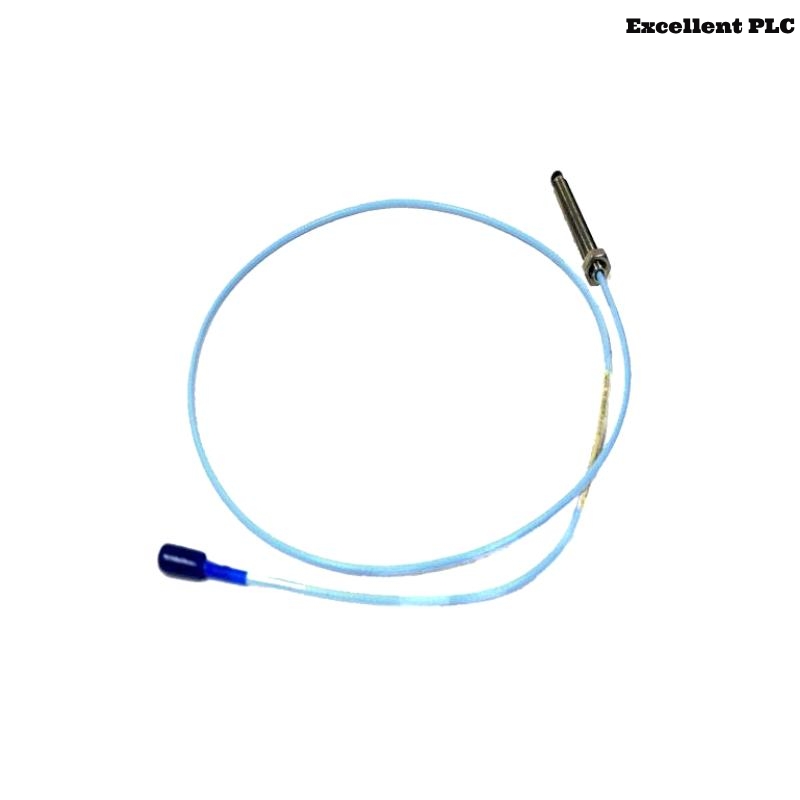

The Bently Nevada 330101-30-63-10-02-00 is a premium component within the 3300 XL 8mm Proximity Transducer System, manufactured by Bently Nevada, a globally recognized leader in machinery condition monitoring and protection. Designed for reliability and precision, this probe delivers consistent performance in harsh industrial environments, including turbines, compressors, pumps, and gearboxes.

As part of the proximity transducer system, it works together with a matching extension cable and Proximitor sensor to provide accurate non-contact measurements of shaft position and vibration. The model adheres to API 670 compliance and is known for its robust mechanical design and electrical stability.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | 330101-30-63-10-02-00 |

| Series | 3300 XL 8mm |

| Tip Diameter | 8 mm (0.315 in) |

| Total Length | 1.0 meter |

| Connector Type | Miniature coaxial connector, 90° molded boot |

| Connector Style Code | 10 (Miniature coaxial male, right angle) |

| Cable Armor Option | 02 (with armor) |

| Thread Size | 3/8-24 UNF-2A |

| Case Material | Stainless Steel |

| Insulation Material | PEEK |

| Operating Temperature Range | -35°C to +177°C |

| Sensing Distance (Range) | 2 mm typical linear range (dependent on material and installation) |

| System Accuracy | ±0.07 mm or better |

| Weight | 0.323 kg |

Product Applications

The 330101-30-63-10-02-00 proximity probe is widely used in a variety of industrial monitoring and protection systems, particularly in:

-

Rotating Machinery Monitoring

Monitors vibration, displacement, and shaft position in motors, turbines, compressors, and generators. -

Critical Machinery Protection Systems

Serves as a key input to vibration and position monitoring systems to protect high-value machinery. -

Condition Monitoring

Enables predictive maintenance by identifying wear, imbalance, and misalignment. -

API 670-Compliant Systems

Frequently integrated into systems where API 670 compliance is mandatory.

Product Advantages

-

High Reliability in Harsh Environments

Designed for extended operation in high-temperature, high-vibration, and contaminated environments. -

Accurate, Repeatable Measurements

Ensures consistent data output with minimal drift over time. -

API 670 Compliance

Meets the strict standards required for critical process industries. -

Ease of Installation and Maintenance

Modular components with standard thread options and connection schemes. -

Superior Mechanical Protection

Armored cabling provides resistance to mechanical damage and chemical exposure. -

Electromagnetic Interference Shielding

Excellent EMI immunity for consistent signal quality.

Frequently Asked Questions (FAQ)

-

What is the sensing range of the 330101-30-63-10-02-00 probe?

The probe typically provides a linear sensing range of 2 mm, optimized for standard 4140 steel targets. -

Is this model suitable for use in hazardous environments?

Yes, the probe is built with robust insulation and shielding, suitable for harsh industrial conditions, though specific hazardous area certifications depend on the complete system. -

Does it comply with API 670 standards?

Yes, this proximity probe system meets API 670 specifications for machinery protection. -

What material is the probe casing made from?

The outer casing is made from corrosion-resistant stainless steel for durability. -

Can the probe be used with extension cables of varying lengths?

Yes, it is designed to work with matched Bently Nevada extension cables and Proximitor sensors as a complete system. -

How should the probe be installed for optimal accuracy?

It should be installed perpendicular to the shaft surface, with proper mechanical mounting to maintain gap integrity. -

What is the connector type used in this model?

This model features a 90° molded mini-coaxial male connector. -

What is the purpose of the armor option in the cable?

The armor offers added mechanical protection against abrasion and damage in industrial settings. -

What is the typical service life of this probe?

With proper installation and use, the probe can last several years under continuous industrial operation. -

Can it be used in high-temperature applications?

Yes, it is rated up to 177°C, making it suitable for many high-temperature industrial processes.

Recommended Related Models (Same Series or Compatible)

| Model | Description |

|---|---|

| 330101-00-12-10-02-00 | 3300 XL 8mm Probe, 12 in, right-angle connector, with armor |

| 330101-00-25-10-02-00 | 3300 XL 8mm Probe, 25 in, armored, right-angle connector |

| 330101-00-05-10-02-00 | 3300 XL 8mm Probe, 5 in, armored |

| 330104-00-05-10-02-00 | 3300 XL NSv Probe for small target applications |

| 330130-040-00-00 | Extension cable for 3300 XL 8mm probes |

| 330180-91-05 | 3300 XL Proximitor Sensor, 5 m system length |

Popular Models from Bently Nevada (Same Brand)

| Model | Description |

|---|---|

| 3500/22M | Key Interface Module for 3500 Series Monitoring Systems |

| 3300 XL 11mm | Proximity Probe System for extended linear range |

| 330104-00-12-10-02-00 | 3300 XL NSv Probe, compact for small target applications |

| 3300/16-14-01-01-00-00 | Monitor Module for speed/acceleration monitoring |

| 3500/42M | Vibration Monitor for 3500 System |

| 330130-085-00-00 | 3300 XL Extension Cable, 8.5 m length |

Excellent PLC

Excellent PLC