| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

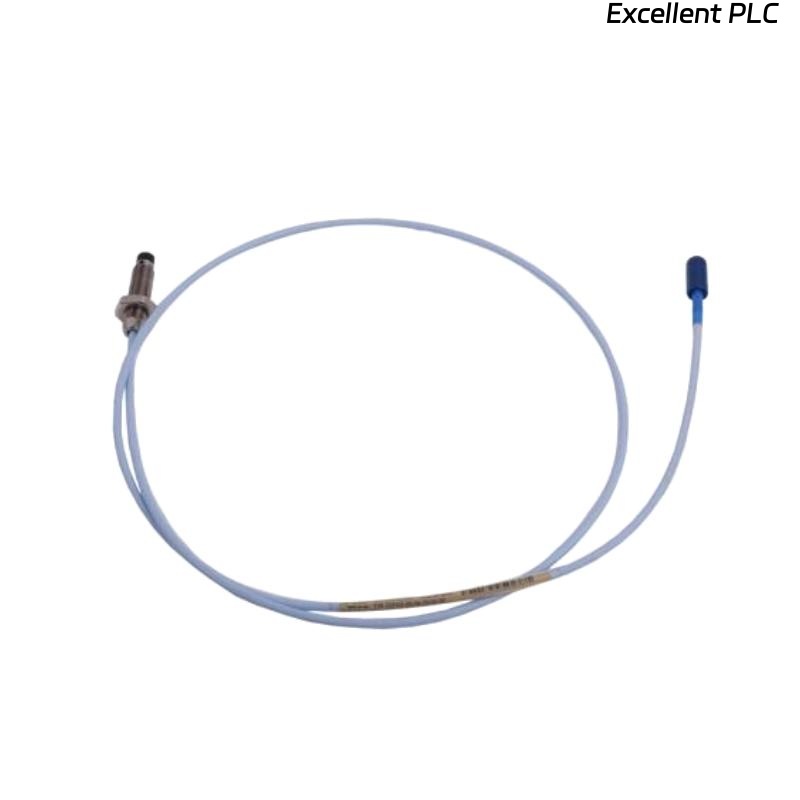

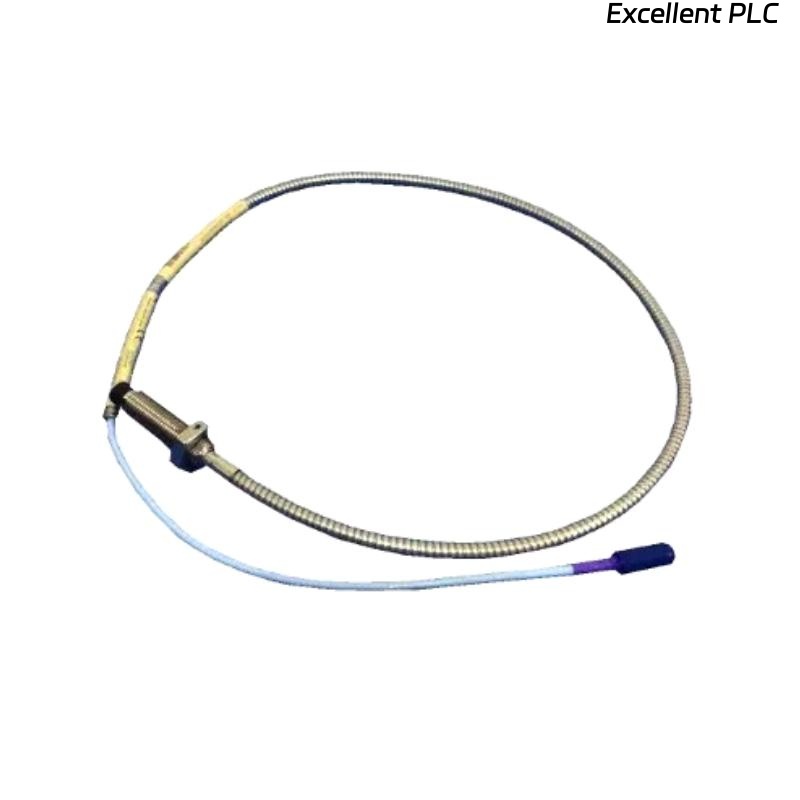

The Bently Nevada 330703-005-040-10-02-00 3300 XL 11 mm Proximity Probe is a high-precision, non-contact vibration and displacement measurement device engineered for demanding industrial applications. Designed as part of the 3300 XL series, this probe represents Bently Nevada’s long-standing commitment to providing reliable and accurate machinery protection and condition monitoring solutions.

This proximity probe utilizes eddy-current sensing technology to detect the distance between the probe tip and a conductive target, such as a rotating shaft. It delivers a highly linear output signal proportional to the target’s displacement, making it ideal for monitoring shaft vibration, axial position, and key phase reference measurements in critical rotating machinery.

The 330703-005-040-10-02-00 is optimized for use with Bently Nevada 3300 XL Proximitor Sensors and extension cables, forming a complete transducer system that complies with API 670 standards for vibration monitoring and machinery protection. Engineered for reliability, it ensures stable signal transmission even under harsh environmental conditions such as oil, heat, and electromagnetic interference (EMI).

Built with corrosion-resistant stainless steel and high-temperature insulation materials, this proximity probe guarantees long-term operational stability and accuracy, making it a trusted component in power generation, oil and gas, petrochemical, and heavy industrial environments.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330703-005-040-10-02-00 |

| Series | 3300 XL 11 mm Proximity Probe |

| Probe Tip Diameter | 11 mm |

| System Compatibility | 3300 XL Proximitor Sensor and extension cable |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linear Range | 0.25 mm to 2.0 mm |

| Linearity | ±1% of full-scale output |

| Frequency Response | 0 to 10 kHz |

| Probe Thread | M14 × 1.5 or ¾-20 UNF (depending on configuration) |

| Mounting Type | Threaded with locknut for secure installation |

| Target Material | AISI 4140 steel (standard calibration target) |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -50°C to +200°C |

| Shock Limit | 500 g peak |

| Vibration Limit | 50 g peak-to-peak |

| Power Supply | Provided via Proximitor Sensor |

| Electrical Isolation | Isolated between probe tip and shield |

| EMI/RFI Protection | Double-shielded coaxial cable |

| Environmental Protection | Oil, dust, and moisture resistant |

| Compliance | API 670, CE, and CSA standards |

| Housing Material | Stainless steel, corrosion-resistant |

| Insulation Resistance | >10⁹ Ω at 500 V DC |

| Weight | 0.07 kg |

Applications

The Bently Nevada 330703-005-040-10-02-00 3300 XL 11 mm Proximity Probe is designed for critical rotating machinery that demands accurate vibration and displacement monitoring. Its versatility makes it suitable for a broad range of industrial sectors and applications.

Typical applications include:

-

Steam and Gas Turbines: Detecting shaft vibration and eccentricity to prevent unplanned shutdowns.

-

Compressors and Pumps: Monitoring bearing and rotor displacement for predictive maintenance.

-

Electric Motors and Generators: Measuring shaft vibration to identify imbalance or misalignment.

-

Gearboxes: Providing precise position feedback to detect wear or looseness.

-

Fans and Blowers: Monitoring mechanical integrity and vibration amplitude.

-

Industrial Machinery: Integration into Bently Nevada 3500 systems for full machinery protection and diagnostics.

This proximity probe ensures accurate and stable operation even under severe environmental conditions such as oil immersion, vibration, or high electromagnetic interference. Its reliability and performance have made it an industry standard in predictive maintenance programs worldwide.

Product Advantages

The 330703-005-040-10-02-00 proximity probe combines advanced engineering, robust construction, and high-performance sensing capabilities. It provides a dependable foundation for monitoring and protecting valuable rotating assets.

Key advantages include:

-

High Precision: Delivers accurate, linear output across the entire measurement range.

-

Robust Design: Stainless steel construction ensures resistance to corrosion and mechanical stress.

-

Superior Signal Integrity: Double-shielded cable minimizes electrical noise and EMI effects.

-

Temperature Stability: Maintains accuracy under extreme temperatures up to +177°C.

-

API 670 Compliance: Fully meets the international standard for machinery protection systems.

-

Compatibility: Seamlessly integrates with 3300 XL Proximitors and Bently Nevada 3500 systems.

-

Environmental Protection: Oil-resistant, moisture-sealed, and vibration-tolerant design.

-

Maintenance-Free Operation: Non-contact sensing eliminates mechanical wear.

-

Ease of Installation: Threaded mounting system provides stable and repeatable installation.

-

Proven Reliability: Extensively field-tested for long-term stability in harsh industrial environments.

FAQ

-

What is the measurement range of the 330703-005-040-10-02-00 proximity probe?

The probe provides a linear measurement range of 0.25 mm to 2.0 mm. -

What type of sensor does this probe work with?

It is designed to operate with the Bently Nevada 3300 XL Proximitor Sensor. -

What is the sensitivity rating of this proximity probe?

The system sensitivity is 200 mV/mil (7.87 mV/μm). -

Can the probe handle strong vibration or shock environments?

Yes, it withstands up to 50 g peak-to-peak vibration and 500 g shock. -

What type of target material is used for calibration?

It is calibrated using AISI 4140 steel as the standard target material. -

Does this probe have electromagnetic shielding?

Yes, it features double-shielded coaxial cabling for effective EMI/RFI protection. -

What is the probe’s operating temperature range?

The operational range is -35°C to +177°C. -

Is the probe suitable for use in oil or moist environments?

Yes, its sealed stainless-steel construction ensures protection against oil and moisture. -

How is the probe mounted to the machinery?

It uses a threaded mounting system with a locknut for secure and repeatable installation. -

What standard does this probe comply with?

It fully complies with API 670 machinery protection standards and CE certifications.

Related or Similar Models

| Model | Description |

|---|---|

| 330703-000-100-10-02-00 | 3300 XL 11 mm probe with standard configuration |

| 330703-000-120-10-02-00 | 3300 XL 11 mm probe, extended measurement option |

| 330703-005-020-10-01-00 | 3300 XL 11 mm probe, short-range configuration |

| 330703-005-060-10-02-00 | 3300 XL 11 mm probe for long-distance setups |

| 330703-005-080-10-02-00 | 3300 XL 11 mm probe with enhanced thermal resistance |

| 330703-005-100-10-02-00 | 3300 XL 11 mm probe, high-stability calibration model |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330130-040-00 | 3300 XL extension cable, 4-meter version |

| 330180-91-05 | 3300 XL Proximitor Sensor, 5-meter system length |

| 3500/42M | Dual-channel vibration and position monitoring module |

| 3500/22M | System communications interface for Bently Nevada 3500 rack |

| 3500/15 | Universal power supply module for 3500 system |

| 330400 | Industrial accelerometer for general-purpose vibration monitoring |

Excellent PLC

Excellent PLC