| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

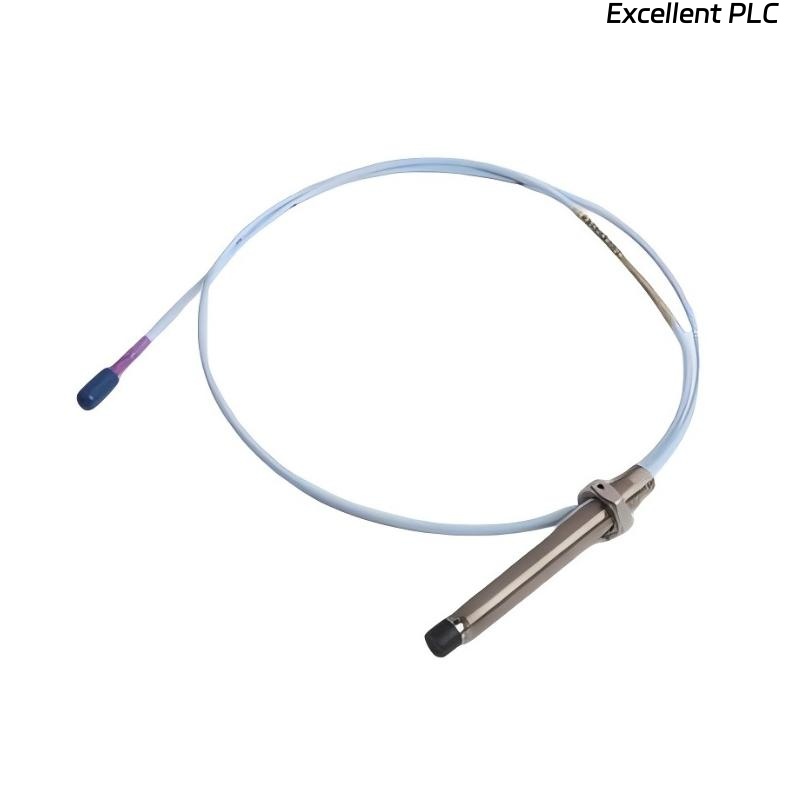

The Bently Nevada 330703-020-110-10-01-05 3300 XL 11 mm Proximity Probe is a high-precision, non-contact vibration and displacement sensor designed specifically for monitoring rotating machinery such as turbines, compressors, motors, and pumps. It belongs to the 3300 XL series, one of the most widely adopted proximity transducer systems in the world for machinery protection and condition monitoring.

This probe functions based on eddy-current sensing technology, detecting the distance between the probe tip and a conductive surface. The electrical signal generated corresponds precisely to the shaft displacement or vibration amplitude. The 330703-020-110-10-01-05 model ensures exceptional linearity, stability, and accuracy, even under challenging operational environments such as high temperature, oil exposure, and mechanical stress.

It works seamlessly with Bently Nevada 3300 XL Proximitor Sensors and compatible extension cables, forming a complete transducer system that adheres to API 670 standards. This makes it a critical element in the preventive maintenance and protection systems of industrial rotating machinery.

The rugged stainless steel design, superior electromagnetic interference protection, and long-term calibration stability make this probe suitable for continuous industrial service where equipment reliability is paramount.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330703-020-110-10-01-05 |

| Series | 3300 XL 11 mm Proximity Probe |

| Probe Tip Diameter | 11 mm |

| System Type | Non-contact eddy-current displacement probe |

| Compatible Sensors | 3300 XL Proximitor Sensors |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linear Range | 0.25 mm to 2.0 mm |

| Linearity Tolerance | ±1% of full-scale output |

| Frequency Response | 0 to 10 kHz |

| Mounting Thread | M14 × 1.5 or ¾-20 UNF |

| Target Material | AISI 4140 steel (standard calibration) |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -50°C to +200°C |

| Shock Resistance | Up to 500 g peak |

| Vibration Limit | Up to 50 g peak-to-peak |

| Probe Housing Material | Stainless steel, corrosion-resistant |

| Insulation Resistance | >10⁹ Ω at 500 V DC |

| Environmental Resistance | Oil, dust, and moisture resistant |

| EMI/RFI Protection | Double-shielded coaxial cable |

| Electrical Isolation | Isolated between probe tip and shield |

| Compliance | API 670, CE, and CSA certified |

| Power Supply | Provided via 3300 XL Proximitor |

| Weight | 0.07 kg |

Applications

The Bently Nevada 330703-020-110-10-01-05 Proximity Probe is specifically engineered for monitoring and protecting high-value rotating machinery where vibration and shaft displacement can indicate mechanical degradation. It is a critical part of predictive maintenance systems used in energy, manufacturing, and petrochemical industries.

Key applications include:

-

Steam and Gas Turbines: Measuring shaft vibration and axial displacement for protection against mechanical failure.

-

Centrifugal Compressors: Detecting rotor instability, imbalance, and bearing wear.

-

Pumps and Blowers: Monitoring shaft movement to prevent excessive vibration and cavitation.

-

Generators and Motors: Measuring shaft position and dynamic movement for predictive maintenance.

-

Gearboxes: Evaluating rotor dynamics and detecting misalignment or mechanical looseness.

-

Industrial Process Equipment: Providing real-time vibration data for automated shutdown or alarm systems.

The probe operates efficiently in extreme environments with exposure to oil, heat, and electromagnetic interference, ensuring continuous reliability in mission-critical machinery.

Product Advantages

The 330703-020-110-10-01-05 3300 XL Proximity Probe provides superior measurement accuracy, robustness, and versatility for industrial condition monitoring applications. Its design and engineering excellence deliver the following advantages:

-

Exceptional Accuracy: High linearity output for reliable shaft vibration and displacement readings.

-

Rugged Design: Stainless steel construction ensures durability and corrosion resistance in harsh environments.

-

API 670 Compliance: Fully meets global standards for machinery protection systems.

-

Wide Operating Range: Performs reliably from -35°C to +177°C with stable calibration.

-

Comprehensive EMI/RFI Shielding: Double-shielded coaxial cable prevents signal distortion from electrical noise.

-

Oil and Moisture Resistant: Sealed design guarantees reliable performance even in oil-contaminated conditions.

-

Easy Integration: Fully compatible with existing Bently Nevada Proximitor and extension cable assemblies.

-

Maintenance-Free Operation: Non-contact measurement eliminates mechanical wear.

-

Fast Dynamic Response: Accurately detects high-frequency vibration components.

-

Proven Reliability: Extensively field-tested for long-term use in critical rotating equipment.

FAQ

-

What measurement principle does the 330703-020-110-10-01-05 probe use?

It operates using eddy-current technology to detect displacement between the probe and a conductive target. -

Which Proximitor Sensor is compatible with this probe?

It is designed for use with the Bently Nevada 3300 XL Proximitor Sensor. -

What is the system sensitivity of this probe?

The probe provides 200 mV/mil (7.87 mV/μm) sensitivity when paired with the correct Proximitor. -

What is the maximum linear measurement range?

The linear range is from 0.25 mm to 2.0 mm. -

Can it operate under high mechanical vibration?

Yes, it can withstand vibration up to 50 g peak-to-peak. -

What material should the target surface be made of?

It is calibrated for AISI 4140 steel, though other conductive materials can be used with appropriate recalibration. -

Does it offer protection against electromagnetic interference?

Yes, its double-shielded coaxial cable ensures full EMI/RFI protection. -

What is the typical frequency response range?

The probe can respond accurately to vibration frequencies up to 10 kHz. -

Is the probe resistant to oil and environmental contaminants?

Yes, it is fully sealed and resistant to oil, dust, and moisture. -

Does the system comply with international standards?

Yes, it fully meets API 670, CE, and CSA certification standards.

Related or Similar Models

| Model | Description |

|---|---|

| 330703-000-100-10-02-00 | Standard 11 mm proximity probe for general monitoring |

| 330703-000-120-10-02-00 | Extended range 11 mm proximity probe |

| 330703-005-040-10-01-00 | Compact probe for short-range measurement |

| 330703-005-040-10-02-00 | Dual-configuration proximity probe |

| 330703-010-070-10-01-CN | High-accuracy probe for precision monitoring |

| 330703-020-110-10-02-00 | Extended performance probe with alternate configuration |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330130-040-00 | 3300 XL 4-meter extension cable for proximity systems |

| 330180-91-05 | 3300 XL Proximitor Sensor, 5-meter system length |

| 3500/42M | Dual-channel vibration and position monitoring module |

| 3500/22M | Communication module for 3500 machinery protection system |

| 3500/15 | Power supply module for 3500 rack configuration |

| 330400 | Industrial accelerometer for vibration condition monitoring |

Excellent PLC

Excellent PLC