| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

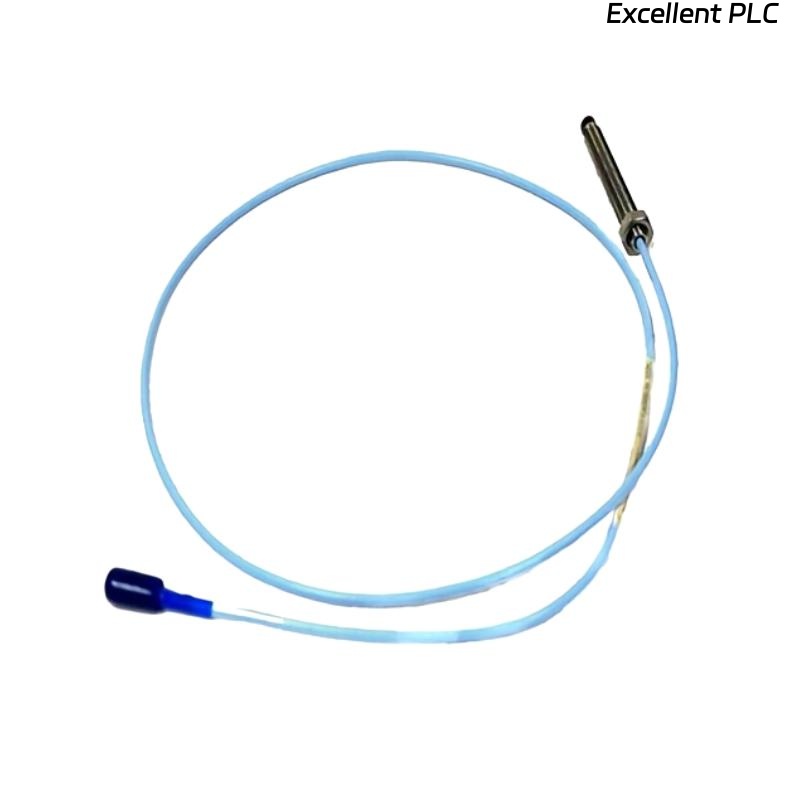

The Bently Nevada 330703-050-120-10-02-00 3300 XL 11 mm Proximity Probe is an advanced non-contact vibration and displacement sensor designed for precision monitoring of rotating machinery such as turbines, compressors, pumps, and motors. It belongs to the 3300 XL series, a globally recognized standard for machinery protection and condition monitoring systems developed by Bently Nevada.

This proximity probe functions based on eddy current sensing technology, where the probe generates an electromagnetic field and detects changes caused by the movement of a conductive target, typically a rotating shaft. The resulting voltage output is directly proportional to the target’s displacement or vibration amplitude, providing real-time data for machinery condition assessment.

The 330703-050-120-10-02-00 model delivers exceptional accuracy and stability, even under extreme industrial environments characterized by high temperature, oil contamination, and electrical interference. When used together with the 3300 XL Proximitor Sensor and compatible extension cables, it forms a complete transducer system compliant with API 670 standards, ensuring reliable and repeatable measurements for both static and dynamic shaft position monitoring.

This probe’s design emphasizes long-term stability, corrosion resistance, and superior linearity. It represents a critical component for predictive maintenance systems in power generation, oil and gas, and heavy machinery industries.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330703-050-120-10-02-00 |

| Series | 3300 XL 11 mm Proximity Probe |

| Measurement Type | Non-contact eddy-current displacement and vibration |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linear Range | 0.25 mm to 2.0 mm |

| Linearity | ±1% of full-scale output |

| Frequency Response | 0 to 10 kHz |

| Probe Tip Diameter | 11 mm |

| Mounting Thread | M14 × 1.5 or ¾-20 UNF |

| Material (Target) | AISI 4140 steel (standard calibration) |

| Operating Temperature | -35°C to +177°C |

| Storage Temperature | -50°C to +200°C |

| Shock Resistance | Up to 500 g peak |

| Vibration Limit | Up to 50 g peak-to-peak |

| Probe Housing Material | Stainless steel (AISI 316), corrosion-resistant |

| Cable Shielding | Double-shielded coaxial, EMI/RFI protected |

| Environmental Resistance | Oil, dust, and moisture resistant |

| Power Supply | Via 3300 XL Proximitor Sensor |

| System Compliance | API 670, CE, CSA certified |

| Isolation Resistance | >10⁹ Ω at 500 V DC |

| Connection Type | Coaxial connector to extension cable |

| Output Signal | Voltage proportional to shaft movement |

| Weight | 0.07 kg |

Applications

The Bently Nevada 330703-050-120-10-02-00 Proximity Probe is specifically designed for continuous vibration and position monitoring of critical rotating equipment. It ensures real-time diagnostic data for predictive maintenance and machinery protection. Its wide temperature range and robust build make it suitable for industrial environments requiring high reliability and measurement accuracy.

Common applications include:

-

Turbines: Measuring shaft displacement and dynamic vibration for detecting unbalance, rubs, or bearing wear.

-

Compressors: Monitoring axial and radial movement to identify instability or rotor misalignment.

-

Pumps and Blowers: Detecting cavitation, imbalance, and mechanical looseness.

-

Motors and Generators: Monitoring shaft position and vibration amplitude for preventive maintenance.

-

Gearboxes: Identifying mechanical resonance or tooth wear through vibration analysis.

-

Industrial Rotating Equipment: Integrating into protection systems that trigger alarms or automatic shutdowns to prevent catastrophic failures.

This probe provides reliable operation in harsh industrial environments such as oil refineries, power plants, and offshore facilities, ensuring continuous monitoring and control of machine health.

Product Advantages

The 330703-050-120-10-02-00 3300 XL Proximity Probe is engineered with Bently Nevada’s proven expertise in machinery monitoring. Its advanced design and construction deliver a combination of performance, durability, and measurement precision unmatched in its class.

Key advantages include:

-

High Measurement Accuracy: Maintains ±1% linearity across the entire measurement range for consistent readings.

-

Rugged Construction: Stainless steel housing resists corrosion, oil, and industrial contaminants.

-

Wide Frequency Response: Capable of detecting both low-frequency shaft displacement and high-frequency vibration events.

-

Superior EMI/RFI Protection: Double-shielded coaxial cable prevents electrical noise interference.

-

API 670 Compliance: Ensures global standard compatibility for machinery protection systems.

-

Thermal Stability: Accurate performance over a broad temperature range (-35°C to +177°C).

-

Oil and Dust Resistance: Sealed design ensures reliable operation in contaminated environments.

-

Maintenance-Free Operation: Non-contact measurement eliminates physical wear and need for recalibration.

-

Seamless System Integration: Fully compatible with all 3300 XL Proximitor Sensors and Bently Nevada extension cables.

-

Trusted Reliability: Decades of proven field performance in critical industrial applications.

FAQ

-

What measurement principle does this probe use?

It operates on the eddy-current principle to detect displacement between the probe tip and a conductive target. -

Which Proximitor Sensor is compatible with this probe?

It is designed for use with the Bently Nevada 3300 XL Proximitor Sensor. -

What is the sensitivity of the 330703-050-120-10-02-00 probe?

The standard system sensitivity is 200 mV/mil (7.87 mV/μm). -

What type of target material should be used for accurate calibration?

The probe is factory-calibrated for AISI 4140 steel. -

How does this probe handle electromagnetic interference?

It features a double-shielded coaxial design for complete EMI/RFI protection. -

What is the probe’s frequency response range?

The probe accurately measures vibration frequencies up to 10 kHz. -

Is it suitable for high-vibration machinery applications?

Yes, it can withstand mechanical vibration up to 50 g peak-to-peak. -

Does it require recalibration during operation?

No, the probe maintains long-term calibration stability under normal use. -

What is the recommended installation thread?

The probe can be mounted using M14 × 1.5 or ¾-20 UNF threads. -

Does the system comply with industrial protection standards?

Yes, it fully meets API 670, CE, and CSA international standards.

Related or Similar Models

| Model | Description |

|---|---|

| 330703-000-100-10-02-00 | Standard 11 mm proximity probe for general-purpose monitoring |

| 330703-000-120-10-02-00 | Extended linear range 11 mm proximity probe |

| 330703-005-040-10-02-00 | Compact probe for short measurement range |

| 330703-010-070-10-01-CN | High-accuracy probe for precision machinery monitoring |

| 330703-020-110-10-02-00 | Long-range probe for heavy-duty rotating equipment |

| 330703-050-120-10-01-00 | Alternate configuration of 11 mm probe with modified output |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330130-040-00 | 3300 XL 4-meter extension cable for proximity probe systems |

| 330180-91-05 | 3300 XL Proximitor Sensor, 5-meter system length |

| 3500/42M | Dual-channel vibration and position monitoring module |

| 3500/22M | Communication interface module for 3500 rack systems |

| 3500/15 | Power supply module for 3500 machinery protection rack |

| 330400 | High-sensitivity accelerometer for industrial vibration monitoring |

Excellent PLC

Excellent PLC